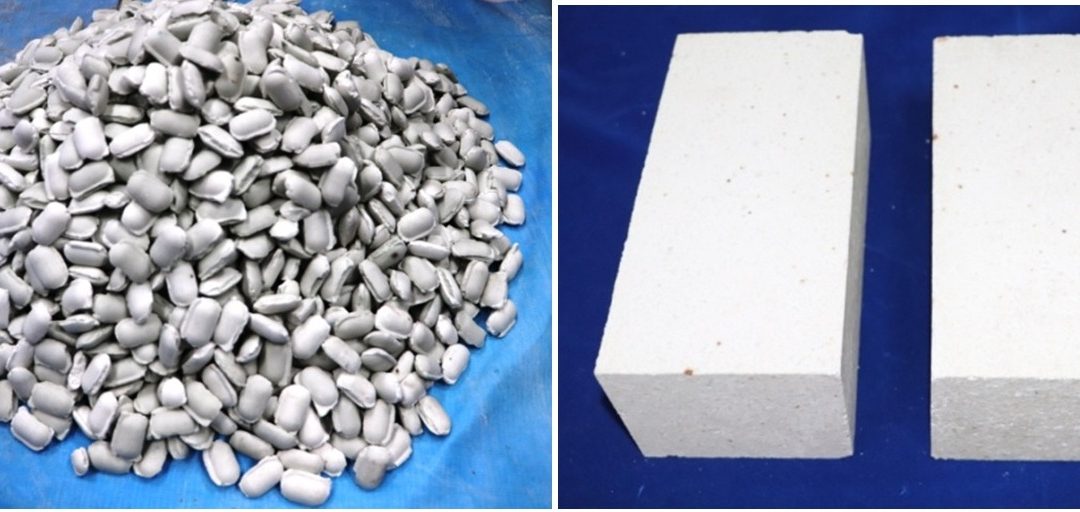

Alumina-based refractories are ubiquitous in several high temperature structural applications and the use of synthetic and purer raw materials for manufacturing of refractory products is a prerequisite for clean steel production. As a part of the work under this vertical, 100 kgs of high alumina (72%) aggregates were developed from sillimanite beach sand (a byproduct of rare earth extraction process of beach sand minerals), calcined alumina and additives through reaction-sintering process. Shaped and unshaped refractory developed from these aggregates showed better properties as compared to commercially available products.

Last Updated on June 26, 2020

Hello sir,

i am from a coastal town in karnataka and a IIT mdras alumnus. we have a small interlock brick making unit @ Karwar. i came across this technology and would like to know more about it. please provide the details to get in touch as we would be interested to try and make commercial use of this technology

Thank you for your comment. It has been forwarded to the concerned group.

Interested to know technology available for utilisation of beachsand sillimanite for making refractory brick in small scale.Capacity,capital and operating cost.