English | हिन्दी

সিএসআইআর-কেন্দ্রীয় কাঁচ ও সেরামিক গবেষণা সংস্থা

सीएसआईआर-केंद्रीय काँच एवं सिरामिक अनुसंधान संस्थान

CSIR-Central Glass & Ceramic Research Institute

"Innovation in Ceramics and Glass for the mankind"

Naroda

CGCRI Naroda Centre, Ahmedabad: Overview

CSIR-CGCRI, Naroda Centre was established in the year 1977 to cater to the needs of the Ceramic Industries in the small and medium scale sectors in Gujarat and adjoining areas with the following main objectives:

- Evaluation and utilization of locally available ceramic raw materials.

- Offering testing facilities to ceramic and allied industries.

- Developing of traditional white ware ceramics.

- Undertaking sponsored research and transfer of technology.

- Technical assistance to the ceramic industries in improving quality, productivity, cost reduction, import substitution and export promotion.

- Training of personnel for manpower development in the ceramic industry.

- Rendering consultancy services to the industry.

- Improvement in rural pottery & development of technologies for diversification in the product range.

The new Innovation and Facilitation Unit of CSIR-CGCRI, Naroda Centre was inaugurated by Hon’ble Minister of State Shri Saurabh Patel and Prof. I. Manna, Director, CSIR-CGCRI.

Areas of Research

Major Activities

- Technology development for the quality improvement of the traditional ceramic products like tiles, sanitary wares etc.

- Development activity for the rural artisans and SMEs Sectors in traditional ceramics for societal benefits

- Utilisation of industrial wastes for the production of traditional Ceramics.

- Beneficiation of the raw materials.

- Development of energy efficient refractory.

- Futuristic research in application of Nano technology in traditional ceramics.

Other Activities

- Technical consultancy to ceramic industries.

CGCRI, Naroda Centre, offers expert services to manufacturers of tiles, sanitaryware, tableware, Insulators, refractories & Kiln furniture and other allied industries such as clay processing industries for practical advice & technical trouble shooting, process improvement, rejection control, product quality improvement, waste utilization and new facilities creation at the manufacturers end. The activities pertaining to optimization of process of manufacturing are also taken up in form of sponsored projects. - Testing and evaluation of ceramic raw materials and products as per relevant standards; IS0 9001:2015.

- Training of personnel for Human Resource Development in the Ceramic Industry.

Technology Developed / Under Development

- Utilization of Dicalcium Phosphate (DCP) in Ceramic Application.

- Standardized process for manufacturing of Emery Stone.

- Technology for Suitable Substitution of various ceramic waste for its gainful utilization in body, engobe and glaze for fired wall tiles.

- Energy saving low mass kiln furniture with higher life for use pottery industries in Ahmedabad region.

- Synthesis of Mullite Grog by calcining china clay and other alumina containing precursor.

- Production of Bone China utilizing the china clays of Gujarat.

- Optimizing process parameters and suggesting suitable remedy for improvement in productivity of stoneware products.

- Technology Upgradation and Development of Terra Cotta clusters in Gujarat State.

- Manufacturing of Glazed Floor Tile utilizing low energy intensive technology for body and glaze production.

- Development of High Alumina Grinding Media.

- Production of Steatite Porcelain for Grinding Media as well as low Loss Insulators.

- Development of High Strength Black Pottery & Kabis

- High strength glazed Terracotta with low temperature lead bearing and leadless glazes.

- Development of Glazes and Engobes for Roofing Tiles.

- Development of low cost floor tile matt engobes utilizing crockeryware scrap powder.

- Development of Glazed Floor tile body utilizing singular blended clays and various ceramic scraps.

- Manufacturing of washed clays and singular blended clay.

- Replacement of Ukrainian clay in the vitrified porcelain tiles production.

- Utilization of fly ash in Traditional Ceramic Products.

- Utilization of Rajpardi clay in Traditional Ceramic Products.

- Patented Technology for Grinding of Ceramic Fired Scrap.

- Technology for manufacturing lead free Blue Pottery.

- Integrated pottery development program for new products and economic upliftment of rural potter.

Projects

Ongoing Projects

|

Sl No. |

Title of the project |

Name of PI |

Project Type (GAP, Consultancy, Sponsored, Research etc) |

Duration |

Funding Agency |

On-going or Completed |

|

1. |

Technical Services Project for (i)Training & Demonstration Programs for outside parties and (ii) Technical advisory reports (iii) Third Party Inspection Work |

Dr. Parag M Solanki |

TSP-0008 |

Continuous |

Various participants / trainees |

On-Going |

|

2. |

Studies on gainful utilization of granite stone waste generated in India in traditional ceramic products |

Dr. Asha Anil |

HCP-54 (WP-08) |

Continuous |

CSIR, New Delhi |

On-Going |

|

3. |

Innovation and research on the development of indigenous technology for manufacturing of single fired white translucent oxidation porcelain crockery |

Dr. Parvesh Agrawal |

OLP-0684 |

Continuous |

Clay Craft India Pvt. Ltd., Jaipur |

On-Going |

|

4. |

CSIR Integrated skill initiative training programme |

Dr. Parvesh Agrawal |

NWP-100 |

Continuous |

CSIR, New Delhi |

On-Going |

|

5. |

Development of low energy intensive (Low temperature maturing and fast firing) vitreous sanitaryware body & glaze for ceramic clusters in Gujarat |

Dr. Asha Anil |

OLP-0701 |

1 Yrs |

CSIR, New Delhi |

On-Going |

Projects completed during last 10 years

|

Sl No. |

Title of the project |

Name of PI |

Project Type (GAP, Consultancy, Sponsored, Research etc) |

Duration |

Funding Agency |

On-going or Completed |

|

1. |

Upgradation of glazing technology and application skills of glazing artisans employed in bone china tableware industries for improving the export potential of this level intensive sector |

Dr. Parvesh Agrawal |

OLP-0637 |

2 Yrs |

Clay Craft India Pvt. Ltd, Jaipur |

Completed |

|

2. |

Imparting Advance Level Pottery Training for Rural Potters with the support of knowledge partner CGCRI, Naroda Centre |

Dr. Parag M Solanki |

GAP-1220 |

3 Yrs |

Gujarat Matikam Kalakai & Rural Technology Institute, Gandhinagar |

Completed |

|

3. |

Integrated Pottery Development Project for Development of Gujarat State’s Pottery Sector |

Dr. Parag M Solanki |

GAP-1218 |

5 Yrs |

Industries and Mines Department, Govt. of Gujarat |

Completed |

|

4. |

Survey of Ceramic Industries of Gujarat to find out technical problems/needs and exploring the findings for possible solution by research institutes |

Dr. Parag M Solanki |

GAP-1219 |

2 Yrs |

Gujarat Council of Science & Technology |

Completed |

|

5. |

Procurement of Inductively Coupled Plasma Spectrometer (ICP) with digester & deionised water equipment for chemical analysis under 60/40 scheme |

Dr. S N Misra |

GAP-1217 |

1 Yr 3 Months |

Jointly by CSIR-CGCRI and Industries Commissionerate, Govt of Gujarat. |

Completed |

|

6. |

Development of Technology for Manufacture of Ceramic Insulator Body and Glaze, Utilizing Locally Available Raw Material |

Dr. S N Misra |

GAP1216 |

3 Yrs |

Industries Commissionerate, Govt of Gujarat (Joint project of CSIR – CGCRI Naroda Centre & ERDA, Vadodara) |

Completed |

|

7. |

An Investigation on the Effect of Solution Based Inorganic Thin Film Coatings on Glazed Ceramic Tiles |

Dr. S N Misra |

GAP-1215 |

2 Yrs |

Gujarat Council of Science & Technology |

Terminated |

|

8. |

Process Standardization of manufacturing of Emery Stone |

Dr. S N Misra |

GAP-1214 |

2 Yrs |

Industries Commissionerate Govt of Gujarat |

Completed |

|

9. |

Modernization of Testing Facilities of CGCRI Naroda Centre under 50/50 scheme |

Dr. S N Misra |

GAP1213 |

4 Yrs |

Industries Commissionerate, Govt of Gujarat |

Completed |

|

10. |

Developmental aspects of double fired wall tiles by suitable substitution of various ceramic waste for its gainful utilization |

Dr. S N Misra |

GAP-1212 |

2 Yrs |

DST, New Delhi |

Completed |

|

11. |

Technology up gradation of development of terracotta cluster in Gujarat state (Wankanar) |

Dr. S N Misra |

GAP-1211 |

2 Yrs |

Gujarat Matikam Board, Govt of Gujarat |

Completed |

|

12. |

Technology Up gradation and Development of Terra Cotta in Gujarat State (Thangad) |

Dr. S N Misra |

GAP-1210 |

2 Yrs |

Gujarat Matikam Kalakari Board; Govt. of Gujarat |

Completed |

|

13. |

Development studies on the energy saving low mass kiln furniture with higher life for pottery industries in Ahmedabad |

Dr. S N Misra |

GAP-1209 |

3 Yrs |

Industries Commissionerate Govt of Gujarat |

Completed |

|

14. |

Development of glazed floor tiles utilizing low energy intensive technology for body and glaze production |

Dr. S N Misra |

GAP-1208 |

2.5 Yrs |

Industries Commissionerate Govt of Gujarat |

Completed |

|

15. |

Futuristic Research Work in Traditional Ceramics |

Dr. S N Misra |

GAP-1207 |

7 Yrs |

Jointly by CSIR-CGCRI and Industries Commissionerate, Govt. of Gujarat |

Completed |

|

16. |

Development of an appropriate beneficiation technique and its implementation of the Than fire clay available at Thangadh and surroundings in Gujarat state for Ceramic Industry |

Dr. S N Misra |

GAP-1206 |

1.5 Yrs |

Industries Commissionerate Govt of Gujarat |

Completed |

|

17. |

Exploration of possibility of utilization of di calcium phosphate (DCP) in ceramic applications |

Dr. S N Misra |

SSP-1216 |

4 Yrs |

Nitta Gelatin India Ltd., Kochi |

Completed

|

|

18. |

Improvement in productivity of stoneware products. |

Dr. S N Misra |

SSP-1215 |

06 months |

M/s Neeldeep Ceramics, M/s Shiv Ceramics, M/s Shivshakti Ceramics |

Completed |

|

19. |

Synthesis of mullite gorg by calcining china clay and other alumina containing precursor |

Dr. S N Misra |

SSP-1214 |

2.25 Yrs |

Mahagujarat Chamunda Cement Co Ltd, Surendranagar Gujarat |

DISCONTINUED BY THE SPONSOR FROM JULY, 2011 |

|

20. |

Standardization of bone china body at Oasis Ceramics Pvt Ltd., Ankleshwar, Gujarat |

Dr. S N Misra |

SSP-1213 |

1.5 Yrs |

Oasis Cements Pvt Ltd, Ankleshwar Gujarat |

Completed |

Divisional Facilities

Major Facilities Available at CSIR-CGCRI, Naroda Centre

Pilot Plant/Materials processing facilities

- Gradient Furnace, Gabbrielli, GmbH (up to 1200oC).

- Roller-hearth kiln (up to 1200oC).

- Hydraulic press for tiles, Gabbrielli, GmbH (specific pressure 300 Kg/cm2).

- Planetary Mixture.

- Ribbon blender.

- Micro pulveriser.

- High alumina mill (10 Kg. capacity).

- Vibro energy mill (10 Kg. capacity).

- Filter press (25 Kg. capacity).

- Magnetic channel.

- Hydraulic classifier, Richard Mozley, UK, Test Rig.

- Electric furnaces of various denominations (up to 1700oC), Agni GmbH, Nabertherm, GmbH, Naskar, Bysakh, etc.

- Gas fired furnace 1200oC.

- Dearing pug mill, Edward & Jones, UK (8mm, 15mm, 25mm dia.).

- Jaw crusher.

- Levigation unit (20 Kg.).

- Ball mills of 10 Kg. to 100 Kg. capacities.

- Raising hearth furnace up to 1600oC.

- Pug mill-Non de-airing.

- Hot air oven (Trey Dryer).

- Pot mill.

- Low temperature water bath.

- Double disc polishing machine.

- Hot plate.

- High speed stirrer.

- Humidifying chambers.

- Centre polishing machine.

- Vicat apparatus.

- Magnetic stirrer.

- pH meter (model .361).

- Vertical autoclave.

- Drying oven for ceramic tiles.

- Electronic balance Mettler Toledo.

- Polishing machine.

Facilities for nano coating:

- Dip coater.

- Spin coater.

- Spray pyrolysis set up.

- Rotary vacuum evaporator.

- Ultrasonic coater.

- Roller furnace for third fired decoration.

- Polishing machine for nano coating.

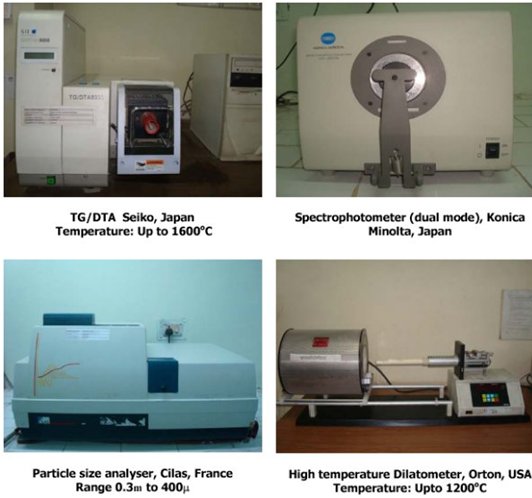

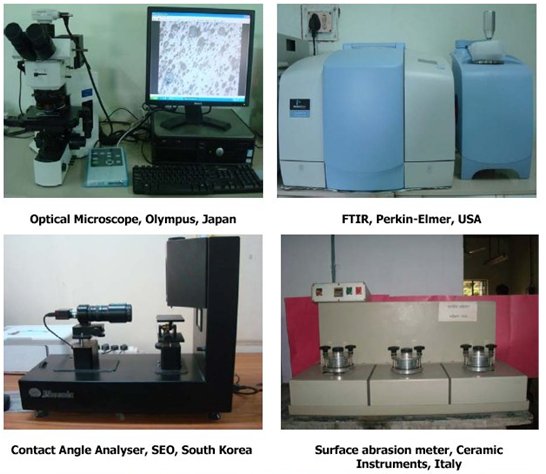

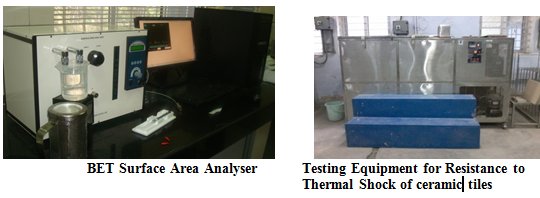

Equipment s for materials characterization:

- X-Ray Diffractometer (Rigaku, Japan)

- ICP (Inductive Couple Plasma Analyzer) with microwave digester.

- Thermal analysis (TG/DTA), Seiko, Japan (up to 1400°C).

- Laser based Particle Size Analyzer (0.3 to 400 µ) Cilas, France.

- Spectrophotometer Konica Minolta., Japan (L, a, b values).

- Glossmeter, Rhopoint, UK.

- Contact angle analyzer.

- Dilatometer, Orton USA (up to 1200oC).

- MOR equipment, Ceramic Instruments, Italy.

- PIE surface abrasion test, Ceramic Instruments, Italy.

- Depth abrasion test, Ceramic Instruments, Italy.

- Autoclaves of different capacities.

- Tank for vacuum water absorption test, Ceramic Instruments, Italy.

- FTIR Spectrometer (Spectrum 100), M/s Perkin Elmer Pvt. Ltd., Singapore.

- Optical microscope model BX-51-N-33-Olympus, Japan.

- Brookfield viscometer (LVDV II*) BET surface area measurement.

- Brookfield rheometer for clay slip viscosity & rheological.

- Slipperiness meter.

- Compression testing machine.

- VEE BEE consistometer.

- Motorized Liquid Limit Device.

- Fast Firing Furnace (1200°C).

- Laboratory fume hoods.

- TC12+ Temperature Calibrator.

- Flame photometer 128.

- UV-VIS Spectrophotometer.

- Digital Vernier Calliper 0-600mm/24″, 0.01mm.

Technical/Support Staff

| Name | Designation |

| Sourav Kumar Das | Senior Technical Officer (2) |

| Kundariya Haresh Karsanbhai | Senior Technical Officer(1) |

| Abhijit Prasad | Senior Technical Officer(1) |

| Akshay Kumar Singh Choudhary | Technical Assistant |

| Pilli Lokesh | Technical Assistant |

| Satyendra Nath Barik | Technician(2) |

| Joshi Naresh Ramanlal | Technician(2) |

| Parekh Rajesh Chunilal | Technician(2) |

| Alpesh Kumar M Patel | Technician(2) |

| Sanjoy Madhu | Technician(2) |

| Ashutosh Sharma | Technician(1) |

| Alisher | Technician(1) |

Scholars/Students

|

Name |

Status |

Project |

Supervisor |

|

Mr. Patel Mihir Kumar |

Technical Assistant (Temporary) |

LRF |

Dr. Parag M Solanki Dr. Asha Anil |

|

Mr. Santosh A Singh |

M.Tech Student |

|

Dr. Parag M Solanki Dr. Parvesh Agarwal |

Contact

Dr. Parag M Solanki,

Chief Scientist & Scientist In-charge

Phone: +91 79 2281 1213/2282 3345

E-mail: siccgcrinc@cgcri.res.in,

pmsolanki@cgcri.res.in

Last Updated on June 11, 2025