English | हिन्दी

সিএসআইআর-কেন্দ্রীয় কাঁচ ও সেরামিক গবেষণা সংস্থা

सीएसआईआर-केंद्रीय काँच एवं सिरामिक अनुसंधान संस्थान

CSIR-Central Glass & Ceramic Research Institute

Refractory & Traditional Ceramics

Overview

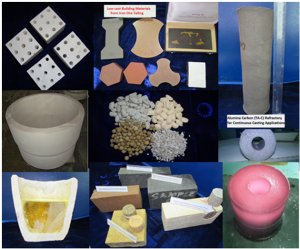

The Refractories Division is instrumental in the development of wide range of refractories for steel, cement, glass and other high temperature processing industries. Several refractory processes developed in the laboratory have been commercialized by the major refractory manufacturers of the country. The department has successfully executed many externally funded projects sponsored by corporate sectors, PSUs and various other government agencies.

The division is primarily engaged in the following activities.

- Refractory raw material research

- Refractory product development

- Refractory testing

- Human resource development in the area of refractory

- Consultancy/technical services

The division is also engaged in the research activities on the gainful utilization of solid wastes generated by iron and steel and other processing industries.

Areas of Research

- Gainful utilisation of Indian refractory raw materials through structural modification(magnesite, bauxite, limestone, dolomite)

- Synthetic refractory aggregates namely, spinel, high alumina from sillimanite beach sand, zirmul etc. through conventional / plasma processing

- Carbon based refractory for steelmaking and functional applications

- Cement and chemically bonded monolithic refractory

- Refractory pot for corrosive glass melting (10 litre to 310 litre)

- Refractory recycling

- Utilisation of solid industrial waste (Iron & steel, mining, power plant etc.)

Technology Developed

Technologies Developed & Transferred

- High alumina brick from beach sand sillimanite (a) chemical bonding (b) ceramic bonding

- Synthetic high alumina aggregate (54-86% Al2O3)

- Low cement castable (45-90% Al2O3)

- Sintered high Al2O3 products (97-99.5% Al2O3)

- Rice husk ash nodules for heat insulation

- High alumina cement free self flowing castable (70-95% Al2O3)

- Mag-chrome aggregate from friable chrome ore

- Rice husk ash insulating brick: (a) phosphate bonding, (b) chemical bonding

- Wear resistant ceramics

- Hydration resistant sintered lime and lime refractory products thereof.

- Magnesia spinel refractory for cement rotary kiln.

Technology under Development

- High alumina aggregates from bauxite of Indian origin

- Plasma fused refractory materials

- Vitrified ceramic tiles utilizing solid industrial wastes

- Functional refractory from sintered alumina

- LC castables for petrochemical and power plant application

- Plastic refractory

Projects

Ongoing Projects

|

Sl. No. |

Title of the Project |

Duration |

Source of Funding |

Principal Investigator |

Co-Investigator (s) |

|

1. |

A study to assess the interaction between hydrogen and the refractory during direct reduction of iron by hydrogen |

2024-27 |

ANRF |

Dr. Somnath Sinhamahapatra |

Dr. Kausik dana |

|

2. |

Effect of in-situ non-oxide reinforcement on the performance & properties of low-carbon Al2O3 -C refractories |

2024-27 |

ANRF |

Dr. Venkatesh Pilli |

Dr. H. S. Tripathi |

|

3. |

New generation refractory materials for blast furnace |

2024-26 |

Private industry |

Dr. H. S. Tripathi (Co-ordinator), Dr. Venkatesh Pilli

|

Dr. Kausik Dana, Dr. Somnath Sinhamahapatra, Mr. Ajitesh Kar, Mr. Ankush Prathap Singh |

|

4. |

MgAlON bonded oxide-non oxide composite refractory |

2024-26 |

CSIR |

Ms. Paromita Das |

Dr. H. S. Tripathi, Dr. Somnath Sinhamahapatra |

|

5. |

Specialty Chemicals for Industrial Applications |

2024-27 |

CSIR |

Dr. H. S. Tripathi |

Dr. Somnath Sinhamahapatra |

|

6. |

Processing of Kimberlite tailings for the production of fuse magnesia |

2023-26 |

CSIR |

Dr. Kausik Dana |

Dr. Somnath Sinhamahapatra |

|

7. |

Refractory Recycling for Sustainable Development

|

2023-26 |

CSIR |

Dr. Somnath Sinhamahapatra |

Dr. H. S. Tripathi, Dr. Kausik Dana, Ms. Paromita Das, Dr. Venkatesh Pilli |

|

8. |

Development and corrosion study of refractory pot SLS glass melting |

2023-24 |

Private industry |

Dr. H. S. Tripathi (Co-ordinator), Dr. Somnath Sinhamahapatra, Dr. Shirshendu Chakraborty |

Mr. S Nag, Mr. B. Haldar, Mr. M. Adhikary, Mr. S. Pasari |

|

9. |

Exploration of Indian Clays for the Development of Functional Materials through Surface Modification

|

2023-26 |

SERB |

Dr. Kausik Dana |

Dr. H. S. Tripathi, Dr. S. Sinhamahapatra, Ms. P Das, Mr. V. P. Reddy, Mr. S. Pasari |

Completed Projects

|

Sl. No. |

Title of the Project |

Duration |

Source of Funding |

Principal Investigator |

Co-Investigator (s) |

|

1. |

Development of suitable binder for processing calcined alumina (in the form of blocks & pallets) in tunnel and rotary kiln without saggers for production of α- alumina

|

2022-24 |

Private industry |

Dr. H. S. Tripathi |

Mr. S. Sinhamahapatra, Mr. Gopal Debnath, Mr. V. P. Reddy |

|

2. |

Development of cost effective refractory lining material for induction melting furnace suitable for production of quality steel : Phase II (Industrial Trials) |

2019-23

|

Govt. Agency |

Dr. H. S. Tripathi |

Dr. K. Dana, Mr. S. Sinhamahapatra, Mr. Gopal Debnath, Mr. V. P. Reddy, Mrs. S. Bose |

|

3. |

Development of Low Carbon MgO-C Refractory for clean steel production. |

2020-22 |

CSIR |

Dr. H. S. Tripathi |

Dr. K. Dana, Mr. S. Sinhamahapatra, Ms. P Das, Mr. V. P. Reddy,

|

|

4. |

Oxide non-oxide composite refractory for high temperature applications utilizing indigenous raw materials |

2019-22 |

SERB |

Dr. H. S. Tripathi |

Dr. K. Dana, Mr. S. Sinhamahapatra, Mr. V. P. Reddy, Mrs. S. Bose |

|

5. |

Synthetic high alumina aggregate from sillimanite beach sand for refractory application |

2018-20 |

CSIR |

Dr. H. S. Tripathi |

Mr. S. Sinhamahapatra |

|

6. |

Superior fused magnesia from impure Indian magnesite for self sustenance |

2018-20 |

CSIR |

Dr. H. S. Tripathi |

Dr. K. Dana |

|

7. |

Characterisation of high carbon ferro chrome slag waste to find out its suitability for refractory applications. |

2018 |

Private industry |

Dr. H. S. Tripathi |

Dr. K. Dana, Mr. S. Sinhamahapatra |

|

8. |

Superior refractory for induction furnace to enable refining of steel |

2017-18 |

CSIR |

Dr. H. S. Tripathi |

Dr. A. Ghosh, Dr. S. Chakraborty, , Dr. K. Dana, Mr. S. Sinhamahapatra |

|

9. |

Development of High Alumina Castable for OPC industry with better Alkali Corrosion resistance ; spalling and abrasion resistance |

2017-18 |

Private industry |

Dr. H. S. Tripathi |

Dr. K. Dana, Mr. S. Sinhamahapatra, Mr. V. P. Reddy |

|

10. |

Development of cost effective refractory lining materials for induction melting furnace suitable for production of quality steel |

2016-18 |

Govt. Agency |

Dr. H. S. Tripathi |

Dr. A. Ghosh, Dr. S. Chakraborty, Mr. V. P. Reddy |

|

11. |

Technology development for the production of speciality refractories through value addition to the indigenously available raw materials |

2012-17 |

CSIR |

Dr. A. Ghosh |

Mr. S. Sinhamahapatra |

|

12. |

Development of refractory aggregates through plasma processing of indigenous refractory raw materials |

2012-17 |

CSIR |

Dr. M. K. Haldar |

Dr. A. Ghosh |

|

13. |

Development of fire-resistant coating on structural element |

2012-17 |

CSIR |

Dr. K Dana |

Mr. S. Sinhamahapatra |

|

14. |

Novel reactive precursors for glass and ceramics |

2012-17 |

CSIR |

Dr. K Dana |

Dr H. S. Tripathi |

|

15. |

Technological intervention and training of artisans in terracotta sector of West Bengal |

2016-17 |

CSIR |

Mr. S. Sinhamahapatra |

Dr. H. S. Tripathi, Dr. K. Dana, Mr. S. Pasari, Mr. S. Roy |

|

16. |

Technological intervention of terracotta sector in Bankura/ South 24 Parganas district of West Bengal |

2016 |

CSIR |

Mr. S. Sinhamahapatra |

Dr. K. Dana, Mr. S. Gupta, Mr. S. Ghosh, Mr. S. Pasari, Mr. S. Roy |

|

17. |

Granular porous ceramic material with engineered pore pattern. |

2015-16 |

Private industry |

Dr. K Dana |

Mr. S. Sinhamahapatra |

|

18. |

Refractory castable for CFBC boiler |

2015-16 |

Public Sector |

Dr. H. S. Tripathi |

Dr. A. Ghosh |

|

19. |

Role of Tabular Alumina in resin bonded alumina-carbon continuous casting refractories |

2014-16 |

Private Industry |

Dr. A. Ghosh |

Dr. H. S. Tripathi Dr. A. Maldhure |

|

20. |

Development of value added high alumina refractory products from Indian bauxite |

2013-15 |

Private Industry |

Dr. H. S. Tripathi |

Mr. S. Sinhamahapatra Dr. A. Ghosh |

|

21. |

High alumina aggregates from sillimanite beach sand and its application in refractory castables |

2013-15 |

Private Industry |

Dr. H. S. Tripathi |

Dr. S. K. Das |

|

22. |

Characterization of Indian lean grade magnesia ore and improvement of its high temperature refractory properties with and without beneficiation |

2012-15 |

Govt. Agency |

Dr. M. K. Haldar |

Dr. A. Ghosh |

|

23. |

Development of cored refractory shapes for air heater |

2014-15 |

Govt. Agency |

Mr. S. Sinhamahapatra |

Dr. A. Ghosh |

|

24. |

Development of aluminosilicate refractory products utilising insulator waste |

2014-15 |

Private Industry |

Dr. H. S. Tripathi |

Dr. A. Ghosh |

|

25. |

Improvement of MgO-C brick quality to enhance the converter life |

2010-14 |

Public Sector |

Dr. A. Ghosh |

Dr. S.K. Das |

|

26. |

Development of newer refractory crucible for melting of corrosive glasses |

2010-14 |

Govt. Agency |

Dr. S.K. Das |

Mr. S. Gupta |

|

27. |

Development of value added ceramic products utilising solid waste generated at VSP |

2011-13 |

Public Sector |

Dr. S. K. Das |

Dr. A. Ghosh |

|

28. |

Development of Corrosion Resistant Glass Contact Al2O3-Cr2O3 |

2009-13 |

Govt. Agency |

Dr. H.S. Tripathi |

Dr. A. Ghosh |

|

29. |

Development of value added Refractory of Aggregate from Indian bauxite of TRL |

2010-12 |

Private Industry |

Dr. A. Ghosh |

Dr. S.K. Das |

|

30. |

Upscaling of hydration resistant lime aggregate & lime refractories thereof |

2008-12 |

Collaborative programme with Industry |

Dr. A. Ghosh |

Dr. S.K. Das |

|

31. |

Al2O3-MgAl2O4 refractory with & without carbon |

2007-10 |

Govt. Agency |

Dr. A. Ghosh |

Dr. H.S. Tripathi |

|

32. |

Vitrified ceramic tiles utilizing sand stone dust of stone processing industries |

2009-10 |

Private Industry |

Dr. S. K. Das |

Dr. M. K. Haldar |

|

33. |

Utilisation of iron ore tailings in making low cost building materials |

2008-09 |

Private Industry |

Dr. S.K. Das |

Mr. N. Singh |

|

34. |

Development of value added refractory products from Indian Bauxite |

2005-08 |

Govt. Agency |

Dr. H.S. Maiti |

Dr. A. Ghosh |

|

35. |

Technology development to manufacture Vitrified Ceramic Tiles utilizing EAF slag |

2007-08 |

Private Industry |

Dr. S.K. Das |

Dr. R. Sarkar |

|

36. |

Plasma processing of industrially important high temperature aggregates |

2003-07 |

Govt. Agency |

Dr. B. Mukherjee |

Dr. A. Ghosh |

|

37. |

Evaluation of High Alumina Ore and Development of Stable refractory aggregates therefrom |

2004-05 |

Govt. Agency |

Dr. M.K. Haldar |

Dr. A. Ghosh |

|

38. |

Development of magnesium aluminate and Mg-chrome spinel aggregates |

2000-04 |

Govt. Agency |

Dr. A. Ghosh |

Dr. Samir Das |

|

39. |

Development of castable based refractory pot |

2000-03 |

Govt. Agency |

Dr. A.C. Das |

Dr. M. K. Haldar |

|

40. |

Development of high temperature ceramic filter for molten metal filtration |

1999-2003 |

In-House |

Dr. S.K. Das |

Mr. P.K. Mondal |

|

41. |

Development of new generation refractory castables |

1998-2002 |

in-house |

Dr. S.K. Das |

Mr. P. K. Mondal |

|

42. |

Characterisation of low grade aluminous ore and development of mullite aggregates and refractories |

2000-2001 |

Govt. Agency |

Dr. B. Mukherjee |

Dr. H.S. Tripathi |

|

43. |

Development of magnesium aluminate spinel aggregates |

1997-1999 |

Overseas Industry |

Dr. Samir Das |

Dr. A. Ghosh |

|

44. |

Development of high density hydration resistant lime sinter and lime refractories for application in steel and cement industries |

1996-1999 |

Govt. Agency |

Dr. G. Banerjee |

Dr. Samir Das |

|

45. |

Development of Mag-chrome aggregates |

1996-1998 |

Private Industry |

Dr. G. Banerjee |

Dr. Samir Das |

|

46. |

Development of technology for critical components in Iron & Steel industry from zirconia powder |

1992-1996 |

Govt. Agency |

Dr. G. Banerjee |

Dr. B. Mukherjee |

|

47. |

Development of magnesite refractories with an inorganic binder |

1995-1996 |

Overseas Industry |

Dr. Samir Das |

Dr. A. Ghosh |

|

48. |

Development of synthetic mullite and zirco-mullite aggregates from beach sand sillamanite and zircon |

1994-1995 |

Private Industry |

Dr. G. Banerjee |

Dr. A. Ghosh |

|

49. |

Development of high density dolomite sinter and dolomite refractories |

1990-1993 |

Private Industry |

Dr. Samir Das |

Dr. A. Ghosh |

Divisional Facilities

|

Processing equipments

|

Characterisation facilities

|

Scientists

Dr. Himansu Sekhar Tripathi, Chief Scientist and Head

Dr. Kausik Dana, Senior Principal Scientist

Dr. Somnath Sinha Mahapatra, Principal Scientist and Leader (Refractory)

Ms. Paromita Das, Scientist

Dr. Venkatesh Pilli, Scientist

Mr. Nelson Kandulna, Scientist

Technical/Support Staff

| Name | Designation | Expertise |

|

Gopal Debnath |

Senior Technical Officer (2) | Refractory Testing |

|

V.P. Reddy |

Senior Technical Officer (1) | Refractory Processing and Testing |

Rajesh Kumar Bahinipati |

Senior Technical Officer (1) | Refractory Testing |

Satyajit Pasari |

Technical Officer | Refractory Processing and Testing |

Souma Bose (Das) |

Technician (2) | Refractory Testing |

Mrityunjay Sardar |

Technician (1) | Refractory Testing |

Anirban Kole |

Technician (1) | Refractory Testing |

Scholars/Students

| Name | Designation | Area of Research | Supervisor |

|

Ms. Smriti Halder |

Project Associate – I |

Exploration of Indian Clays for the Development of Functional Materials through Surface Modification

|

Dr. Kausik Dana |

Ms. Aarya Bhardowaz |

Project Associate – I | Refractory Recycling for Sustainable Development | Dr. Somnath Sinhamahapatra |

Ms. Aditi Das |

Project Associate – I | Refractory Recycling for Sustainable Development | Dr. Somnath Sinhamahapatra |

Ms. Madhurima Kundu |

Project Assistant | Development and corrosion study of refractory pot SLS glass melting | Dr. Somnath Sinhamahapatra |

Ms. Priyanka Mudi |

Project Associate – I | Specialty Chemicals for Industrial Applications | Dr. H.S. Tripathi |

Mr. Dipanjan Ash |

Project Associate – I | New generation refractory materials for blast furnace | Dr. Venkatesh Pilli |

Contact

Dr. Himansu Sekhar Tripathi,

Chief Scientist & Head

Phone: +91-33-2322 3480

Fax: +91-33-24730957

E-mail: hstripathi@cgcri.res.in

Last Updated on July 15, 2024