English | हिन्दी

সিএসআইআর-কেন্দ্রীয় কাঁচ ও সেরামিক গবেষণা সংস্থা

सीएसआईआर-केंद्रीय काँच एवं सिरामिक अनुसंधान संस्थान

CSIR-Central Glass & Ceramic Research Institute

Materials Characterization

Overview

Materials Characterization Division (MCD) offers comprehensive techniques and capabilities that are crucial to modern materials research and analysis to draw composition-structure-property correlations in ceramics, glass, metals, and composite materials important for both academic Institutes and Industry. Facilities at MCID can provide information about the thermal and physical properties and chemical state of elements in a wide variety of materials. The Division houses various state-of-the-art instruments for characterizing various aspects of materials. These include Atomic and molecular spectroscopy based techniques like Inductively Coupled Plasma Mass Spectroscopy (ICP-MS), Inductively Coupled Plasma Atomic Emission Spectroscopy (ICP-AES), Flame Atomic Absorption Spectroscopy (FAAS), UV-Visible Spectrophotometry, CNO analyzer. There are various other instrumented characterization techniques like Differential Thermal Analysis (DTA), Thermo-Gravimetric Analysis (TGA), Differential Scanning Calorimetry (DSC), Dilatometry, Themal Conductivity, Rheometry, Porosimetry, Particle Size Analysis, Gas Pycnometer, etc. which are employed by the Division for characterization of the various thermo-physical properties of materials to contribute to the institute’s various R&D activities on wide variety of materials. The Division has a major activity for the development of analytical methods for chemical characterization of glass, ceramic and allied materials, metals and environmental samples related to all the projects of the institute as well as different glass, ceramic and other industries, universities, research organizations etc. Primary objective of Materials Characterization Division is to develop analysis tools and methodologies to promote multidisciplinary research for better understanding of composition-structure-properties correlation.

Areas of Research

- Development of atomic and molecular spectroscopic techniques using Inductively Coupled Plasma Mass Spectrometry (ICP MS), Inductively Coupled Plasma Atomic Emission Spectrometry (ICP AES), Flame Atomic Absorption Spectrometry (FAAS), UV-VIS Spectrophotometry.

- Development of solid phase extraction technique using polyurethane foam (PUF) for separation, pre-concentration and analysis of trace and ultra trace elements

- Development of chemical processes for separation and removal of toxic elements from waste water.

- Development of analytical methods for the extraction of precious metals from waste materials.

- Study of Rheological and magnetoreological properties of Ferro fluids and MR fluids.

- Study of thermal (DTA, TGA, DSC, Thermal Conducvity) and physical characteristics (Particle Size, Surface Area, Porosimetry) of different glass and ceramic materials and evaluation of specific heat, phase transitions, softening point and glass transition temperatures, viscous and elastic modulus, creep and yield study and pore size and its morphology thereof.

- Analysis of C/N2/O2 content (ppm to percentage) in any type of solid sample by CNO analyzer and measurement of true density of any shape of porous or solid sample by Helium Gas Picnometer.

- Development of measurement set-up comprising of different type of platinum electrodes for study of electrical conductivity of lead glass systems and borosilicate glass beads in molten as well as solid conditions.

- Development, characterization, calibration and telemetry of sensors for bio medical applications.

- Synthesis and characterization of nanostructured ZnO thin films for dynamic strain sensing.

Technology Developed

Projects

| Sl No | Title of project | Duration | Source of funding | Principal investigator | Co-investigators |

| 1. | Development, characterization and testing of minimal invasive micro system for the monitoring of intra ocular pressure, sub-task under Development of Novel CSIR Technologies for Manufacturing Tailored and Patient-specific Bioceramic Implants and Biomedical Devices at Affordable Cost (ESC0103). | 2012-2017 | CSIR | Ashim Kumar Chakraborty | Mousumi Majumder |

| 2. | Development of analytical methods for chemical characterization of glass and ceramic materials. | 2014 – 2015 | In House Project | Dr. P. K. Sinha | Ashim Kumar Chakraborty |

| 3. | Development of Seven Components Borosilicate Glass Beads. | 2014-2016 | NRB, DAE | Sitendu Mandal | Santanu Sen (Co-PI), Dr. Dipali Kundu (Co-PI), Ashim Kr. Chakraborty, Dr.Ranjan Sen |

| 4. | Energy efficient, cost effective method for preparation of specialty glass by dielectric heating. (12th Five Year Plan Project) | 2012-2017 | CSIR | Ashis Kumar Mondal | Santanu Sen. Dr.Ranjan Sen, Ashim Kr. Chakraborty |

| 5. | Development of manufacturing technology and supply of radiation shielding window glass blocks (5.2gms/cc) to BARC (DAE) for hot cell application. (MOU-I & II completed & MOU-III is in process) | 2001-2015 | DAE | Dr. Ranjan Sen | Sitendu Mondal, Ashim Kr. Chakraborty, Santanu Sen |

Completed Projects

| Sl No | Title of project | Duration | Source of funding | Principal investigator | Co-investigators |

| 1. | Development of analytical methods for chemical characterization of glass and ceramic materials. | 2012 – 2013 | CSIR | Dr. Dipali Kundu | Dr. P. K. Sinha |

| 2. | Development, production and supply of Neodymium doped phosphate laser glass (square cylinders for use in high power glass lasers). | 2011-2013 | BRNS | Dr. Ranjan Sen | Dr. Dipali Kundu Dr. P. K. Sinha |

| 3. | Study of electrical conductivity of SiO2-PbO-K2O glass systems and SiO2-B2O5-K2 O) glass nodules in the molten condition at high temperature. | 2011-2013 | CSIR | Santanu Sen | Ashim Kr Chakraborty, Sitendu Mondal |

| 4. | Development, synthesis, characterization and thermo-physical property measurement of ceramic nanoparticles dispersed nanofluids for thermal applications | 2010-2013 | CSIR | Dr. Indranil Manna | Mousumi Majumder (Co-PI) |

| 5. | Proficiency testing under NABL programme on complexometric determination of Alumina, Titania and iron oxide in China Clay. | 2000 – 2001 | DST | Dr. Dipali Kundu | Dr. P. K. Sinha |

| 6. | “Fibre Bragg Grating (FBG) as Strain Sensor” Sub-Task 2 of Task 4, Technology for Engineering Critical Assessment (TECA), COR 0022. | April 2002 – March 2007 | CSIR | Ashim Kumar Chakraborty | Dr.T.K.Gangopadhyay, Mousumi Majumder, Kamal Dasgupta, D.K.Bhattacharya |

| 7. | Determination of softening point and the working range of different glasses through viscosity measurement (OLP 0091). | 2003 – 2006 | CSIR | Ashim Kumar Chakraborty | Mousumi Majumder, Santanu Sen |

| 8. | Development of thyristor power controller (5 KW) for use with electrical furnace: OLP 180109. | April 2002 to June 2003 | CSIR | Ashim Kumar Chakraborty | Mousumi Majumder, Santanu Sen, Asit Maiti |

Divisional Facilities

Central Materials Characterization Facility |

STA 449, RT to 1600, Netzsch |

|

Twin Surface area analyzer, Quantachrome) |

Dilatometer (RT to 1600o C), Netzsch |

|

Rheometer, Malvern |

Rheometer with magneto rheology attachment |

|

Microparticle Analyzer, Methrom |

Zetasizer, Malvern |

|

Gas Pycnometer, Micromeritics |

Inductively Coupled Plasma Mass Spectrometer (ICP-MS), Perkin-Elmer |

|

Inductively Coupled Plasma Atomic Emission Spectrometer (ICP-AES), Spectro Analytical |

Flame Atomic Absorption Spectrophotometer (FAAS), Perkin Elmer |

|

UV-VIS Spectrophotometer |

Flame Photometer |

|

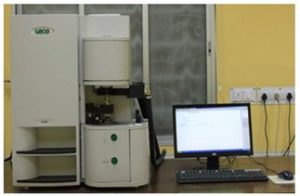

Carbon Analyser, LECO |

Nitrogen & Oxygen Analyser, LECO |

|

Scientists

Dr. Tarun Kumar Kayal, Chief Scientist and Head

Dr. Sandip Bysakh, Senior Principal Scientist, Leader (TEM/ XPS/FIB)

Dr. Mousumi Majumder Senior Principal Scientist, Leader (Central Material Characterization Facility)

Dr. Jiten Ghosh, Senior Principal Scientist, Leader (XRD/GAXRD/XRF/FESEM)

Dr. Prabir Pal, Principal Scientist

Technical/Support Staff

| Name | Designation | Expertise / Capability |

| Ashok Kumar Mandal | Senior Technical Officer (2) | FE-SEM |

Swati Samanta |

Senior Technical Officer(2) | Operation and maintenance of STA, Particle size analyser, Rheometer including magneto rheology, MIP, SAA, Dilatometer, Thermal constant analyser. Operation& maintenance of EPABX, including line fault repair, new intercom connection, maintenance of P & T lines etc. |

| Prosenjit Khan | Senior Technical Officer (1) | XRD-XRF |

| Titir Maity | Senior Technical Officer (1) | |

| Kajari Dasgupta | Senior Technical Officer (1) | |

| Nitai Dey | Senior Technical Officer (1) | FE-SEM |

Mousumi Baral Narjinary |

Senior Technical Officer (1) | Material processing, sensor platform fabrication, characterization of sensors. |

|

Senior Technical Officer (1) | Operation and maintenance of STA, Particle size Analyzer including zeta potential measurement, Rheometer , Hot disk thermal constant Analyzer & FTIR |

| Subash Sharma | Technical Assistant | |

| Sumit Nath | Technician (2) | |

| Bholanath Jana | Laboratory Assistant | FE-SEM |

Scholars/Students

| Name | Status | Project | Co-Supervisor |

Last Updated on June 26, 2024