English | हिन्दी

সিএসআইআর-কেন্দ্রীয় কাঁচ ও সেরামিক গবেষণা সংস্থা

सीएसआईआर-केंद्रीय काँच एवं सिरामिक अनुसंधान संस्थान

CSIR-Central Glass & Ceramic Research Institute

"Innovation in Ceramics and Glass for the mankind"

Legacy

Genesis and First Steps

PRELUDE

Glass manufacture, even in its simplest form is highly technical and calls for a sound understanding of physics, chemistry and engineering for furnace design. It demands technically skilled workers. The development of glass is the story of the application of scientific methods to industrial production. Optimal marketing arrangements are needed too. None of this was forthcoming in pre-Independence India. At that time, the unorganized sector was the leading producer of glass.

As early as in 1916 The Indian Industrial Commission had noted in its report,

“An organisation is wanted to take up the whole industry, including men who can deal with the furnace problem, the preparation of refractory material for furnaces, crucibles and pots, the chemistry of glass, the manipulation of the crude products and its conversion into finished forms, whether by skilled blowers or by highly complex and semi-automated machinery…”

Yet the situation did not change and the glass industry languished till in 1931 a Tariff Board was set up.

The Tariff Board, in its turn, noted; “The difficulties experienced by Indian manufacturers of glass are to be attributed largely to the lack of adequate provision for the investigation of scientific problems connected with the industry and for the training of managers possessing the requisite knowledge of technology and modern methods of manufacture.” Still, the situation was not remedied.

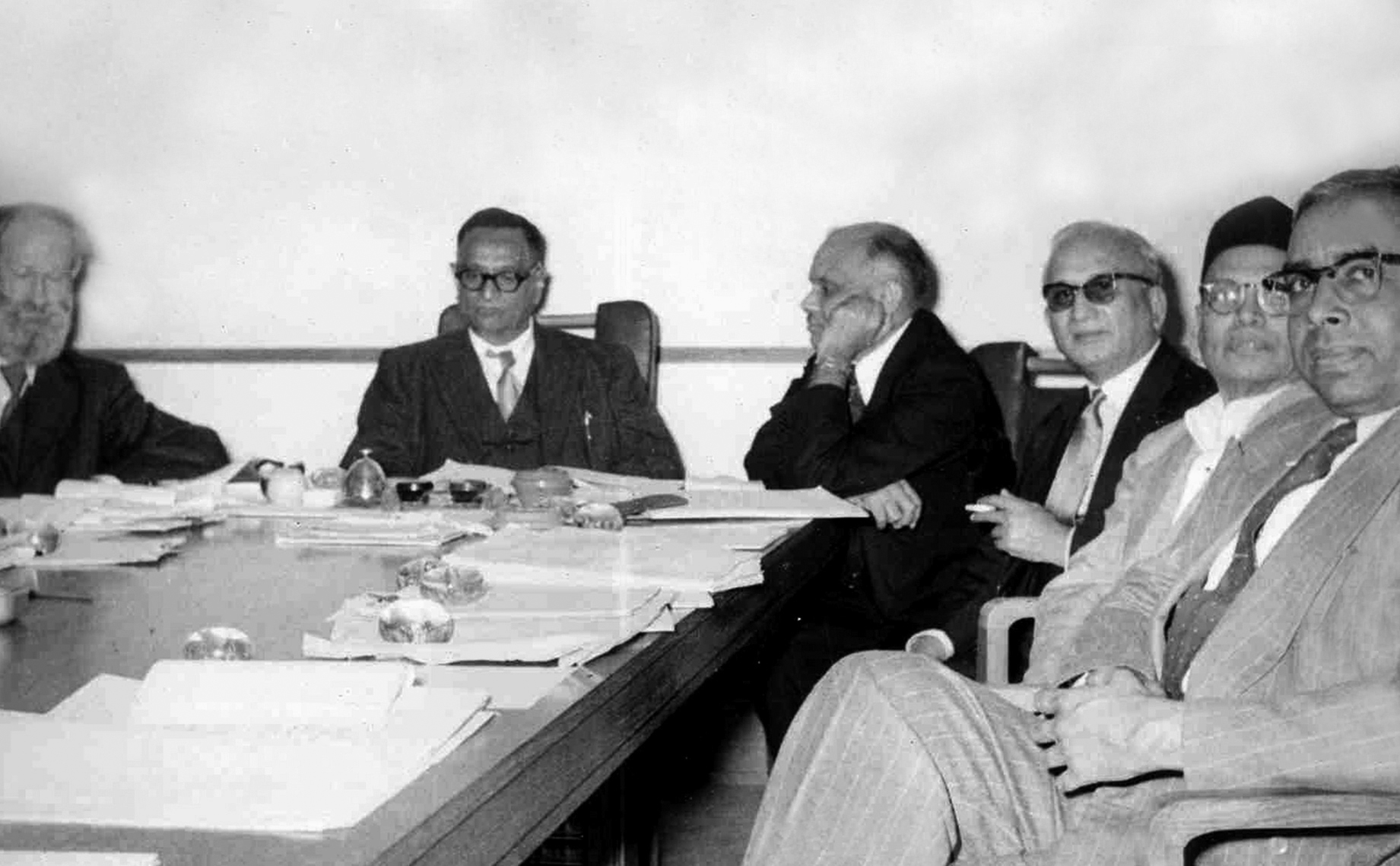

The first step was taken in April 1940, when the Board of Scientific and Industrial Research (BSIR) was established bringing on board eminent scientists and industrialists. It was a purely advisory body. Dr. Arcot Ramaswamy Mudaliar was ex-officio Chairman.

The Council of Scientific and Industrial Research (CSIR) was registered as a Society on 26 September 1942 under the Registration of Societies Act XXI of 1860.

To evaluate modern India’s contribution to glass research, the genesis of the Council of Scientific and Industrial Research (CSIR) has to be understood in the context of time.

TIMELINE

The Glass and Refractories Committee was constituted on 9 July 1940 under the Chairmanship of Dr. A. Nadel who was succeeded by M.G, Bhagat.

The schemes that were then in operation included: manufacture of optical glass; manufacture of ceramic colours and glazes; high temperature refractories used in glass industry; purification of Indian glass-making sands and classification of Indian moulding sands and clays.

In 1941 eminent scientist and Editor of Science and Culture, Prof. Meghnad Saha argued; “If the glass industry in India has to be placed on a firm basis, it is of immediate importance that there should be a School of Glass Technology in a suitable centre which will arrange for adequate and effective provisions for training and research with the objectives: (i) Training of students in glass technologies including refractory and fuels, (ii) carrying out investigations for the benefit of Industry and also, fundamental research, (iii) testing, and standardization of raw materials, refractories, finished glassware, etc, and (iv) giving technical advice to the Industry whenever necessary.”

This galvanized the stalwarts of Indian science into action. In 1937, the first-ever Department of Glass Technology had been set up at the Benares Hindu University (BHU) to complement the existing Department of Ceramics. Prof. Meghnad Saha and Dr. Shanti Swarup Bhatnagar (the founding father of CSIR), visited BHU with the idea of utilizing the setup there to formalize an Institute of Glass Research. Subsequently, they submitted a report to the BSIR. In March 1942, the BSIR appointed a Central Glass Research Institute Committee to advise it.

In 1943, at the fourth meeting of CSIR at New Delhi under the Chairmanship of Hon’ble Sir Muhammed Azizul Haque, the-then Member of Commerce the BSIR recommended “..organization of the Central Glass and Silicate Research Institute…….”. This institute would finally be named The Central Glass and Ceramic Research Institute (CGCRI).

CGCRI was established in Calcutta (now Kolkata) because of its strategic location involving proximity to mines, quarries and coal-fields. Dr. Bhatnagar’s rationale behind choosing Calcutta added more reasons. “We have chosen Calcutta for the location of the Institute as it is one of the principal centres of the glass and ceramic industry. For the establishment of a successful glass and ceramic industry, we are as much dependent on science and technology as on decorative and creative art requiring delicate touches which only deft hands can impart, and as we know that Bengal possesses artistic talents which few others can equal, as well as scientific acumen of a high order, we feel we have acted rightly in locating the Institute, here.”

THE STORY BEGINS

CSIR-CGCRI is one of the first four laboratories set up under the Council of Scientific & Industrial Research.

Preliminary estimated costs for setting up Central Glass Research Institute was Rs. 1,71,000 (Capital) + Rs. 1,30,000(Recurring). The initial grant received was Rs 12 lakhs along with contributions of Rs 10,000 each from Bengal Glass Manufacturer Association, Dr. I.N. Varsheney and Sir U.N. Brahmachari.

At the behest of the Mayor of Calcutta, the authorities of Jadavpur College offered 5 bighas of land for the nominal sum of Rs One per acre for 99 years.

M/s Ballardie, Thompson and Mathew were chosen to be the architects. Construction began on 1 September 1945.

The Foundation Stone of the Institute was laid by the Hon’ble Ardeshir Dalal on 24 December 1945.

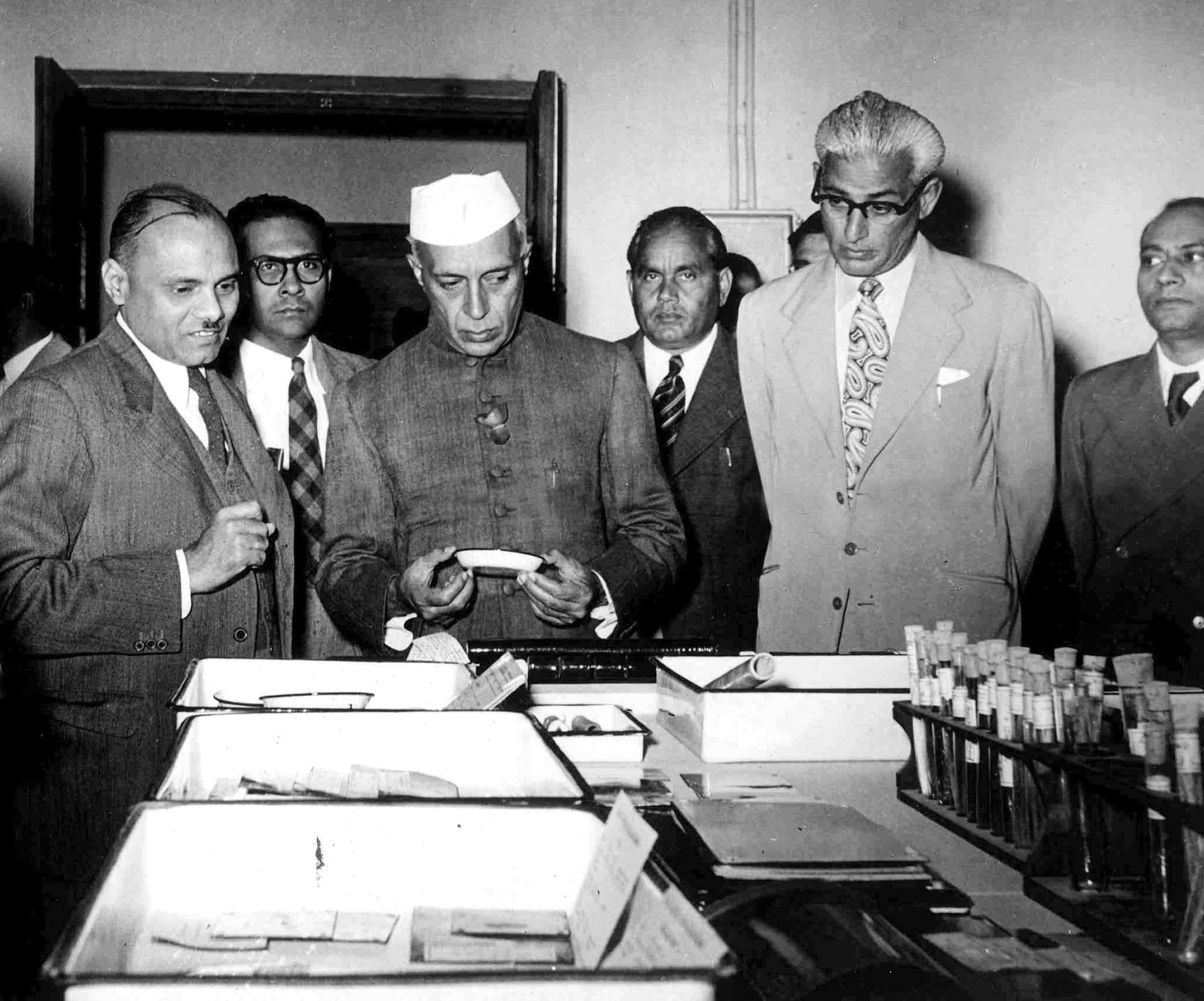

CSIR-CGCRI had actually started functioning in a limited way in 1944. The Institute was formally inaugurated on 26August 1950 by Dr. Bidhan Chandra Roy, the-then Chief Minister of West Bengal. It one of the six CSIR laboratories that came into being that year.

Even today, the Institute still has the distinction of being the only one of its kind in India and one of only a handful in the entire Asia Pacific region.

Past Contributions

FIRST STEPS

The new Institute was dedicated to scientific and industrial/applied research of national importance in the fields of glass, ceramics, refractories, vitreous enamels and mica.

It would undertake R&D directed towards identifying mineral resources and focus on proper utilization of the country’s resources of related materials; import substitution; meet felt needs of the country, assisting the industry and carry out basic research. The ambit of the proposed institute included pottery, refractories, and enamels in addition to glass.

Dr. Atmaram, the first Director of CGCRI was of the opinion that indigenous research should focus on “…areas of felt needs…”, and which others have not touched should have greater attention in the country’s research.

A typical example of an area of felt need was the glass bangle industry in Firozabad, which was starved of an imported material for producing red bangles. The industry, specific to India and Pakistan produced Rs 4.5 crore worth of goods. Nobody abroad was interested in this Industry. Yet, this was an important field of applied research as it was linked to the cultural landscape of India. Very soon, the nation began to produce red glass without using any imported colouring ingredient.

The first decade of its existence saw all-round research activities. Much of the work was directed towards identifying suitable mineral resources within the country and evaluating their suitability for specific product development. The quality control aspects in glass and ceramic received due attention and so was the work on glass forming machines and glass-lined equipment. Samples of Green stepped lenses were tested by the Government Inspector of Railways. Red lenses using substitutes of selenium as colourants, Lunar white and colour-less White stepped lenses were also prepared. Eight new on-glaze colours that compared favourably with imported Blythe’s colours were formulated. CGCRI dedicated its efforts towards using copper-ruby glasses for making the red bangles mandatorily worn by married women.

CGCRI’s stepping into sixties coincided with a very important milestone in the history of the economic development of the country. At that point of time, Optical glass was produced in only a few countries of the world and its production technology was kept a carefully guarded secret. CGCRI developed this glass without any foreign collaboration whatsoever. The Institute’s indigenous pilot plant with an annual capacity of 10 tonnes went into production in 1961 and opened up new vistas in the field of optical industries in India.

Development of various types of optical glasses brought CGCRI into limelight in the international arena and the nascent nation now had access to an indigenously produced strategic material much in demand in scientific circles.

Optical glass is used as lenses and prisms for making periscopes, binoculars, range-finders, gun-sights, fire directors, and scientific, photographic and survey instruments such as microscopes, telescopes, cameras, projectors, and theodolites etc. Its scientific and technological usefulness needs no reiteration.

In the seventies CGCRI explored the fields of laser glass, infra-red transmitting filters, synthetic quartz single crystal, high temperature protective enamels, high alumina ceramic seals and spacers. Research work on foam glass, glass bonded mica, steel plant refractories went on in top gear.

In the eighties CGCRI entered the field of optical fibre for telecommunications, sol-gel processing of glass and ceramic materials, production of glass fibre based composites and application of ceramic materials in electronics.

Special attention was paid to the small-scale sector and CGCRI established two extension centres; one each at Naroda (Gujarat) and Khurja (UP) with the partial financial assistance from the respective state Governments. The know-how generated by CGCRI for production of potteries based on locally available clay in Bankura (West Bengal) catalyzed the establishment of the Ceramic Centre for Rural Development, Pachmura, Bankura.

In retrospect it is clear that there was a pattern to the evolution of the Institute during Pre-Liberalization Period

Years of technology denial particularly for the strategic sector was the challenge that led to CSIR-CGCRI’s acquiring of core knowledgebase in these domains based on solid indigenous efforts. Import substitution was the keyword. Apart from Optical glasses the other major advancements during this period include the creating and casting of radiation shielding glasses for atomic energy establishments; and R&D on laser glasses. Over the years, CSIR-CGCRI emerged as the key backward linkage for major technological missions in atomic energy, defence and space. It accelerated indigenization of product/process development and import substitution for raw materials and components.

In the nineties, when the winds of liberalization began to blow, CSIR-CGCRI placed major emphasis on (i) National security or strategic, (ii) Industrial development and (iii) Societal activities. Sectors such as Energy, Water, Health Care, Communication and Instrumentation came under sharp focus.

Post-Liberalization Period

New opportunities were explored and utilised during the post liberalisation period. Enhanced funding support as well as the new policy of inter-institutional networking opened new vistas for the institution. The Institute diversified into many hitherto unexplored areas such as fibre optics, photonics, optical communication fibres, specialty glasses, non-oxide ceramics, electro-ceramics with application to renewable energy, bio-ceramics and coatings with healthcare and bio-medical engineering applications, ceramic membrane technologies with application to water purification etc. Nano materials, nano-composites and sensors were new areas that were accorded significant priority. The institute also emerged into a one-stop facility for testing, characterisation and evaluation of materials.

Transformation and Repositioning during the New Millennium

CSIR-CGCRI realigned itself in synergy with CSIR’s vision for 2022 by developing innovative technology solutions through trans-disciplinary science and engineering undertaken in mission mode. Several programmes were created to focus on science- based entrepreneurship and socio-economic transformation through participative science and participatory technology development in identified domains. While retaining its ambit of defence, atomic energy and space, new forays were made to also cover stakeholders from railways, oil & natural gas, mines, MSME, rural development, public health engineering, water resources, and renewable energy.

CSIR-CGCRI”s portfolio showed enviable diversity encompassing every sector of society.

Accelerating Inclusive Growth through Entrepreneurship

The institute’s Outreach Centres at Khurja and Naroda have been instrumental in driving entrepreneurship development through technology mentoring, skill development and capacity building. Notable achievements have been the replacement of Ukrainian clay in tile making, agglomerating a tiles cluster at Morvy, developing entrepreneurship in glass bead making in Uttar Pradesh, assistance to rural potters and so on. The institute was also identified to serve as CSIR’s single-window centre for technology enablement of MSME sector of West Bengal.

Creation of Trans-Disciplinary Human Resources

The institute has trained innumerable students in diverse fields of materials science and engineering covering domains of fibre optics, glass, bio-ceramics, electro-ceramics, and nano-materials to name a few. That the role of CSIR-CGCRI in empowering HR is appreciated by the student community is reflected in the progressive increase in number of PhD students enrolled and graduated over the years.

Currently, CSIR-CGCRI offers tailored courses in Advanced Glass Science and Technology in association with the Academy of Scientific and Innovative Research (AcSIR).

Recent Thrust Areas

There is enhanced focus on translational research initiatives aimed at linking its technological knowledge base to diverse stakeholders. While consolidating its core strengths in the strategic sector, the institute is poised to play an enabling role in the sectors of materials and manufacturing through science, technology and innovation.

In a Nut-shell

The entire history of CSIR-CGCRI’s evolution against an ever-changing backdrop of emerging India makes a fascinating study in learning how the institution was conceived, nurtured and guided to grow into a mammoth S&T structure underpinning, to a greater or lesser extent, almost all of modern India’s S&T ventures in the field of glass and ceramics.

In the very early days, import substitution was the watchword. CGCRI developed boron-free enamels, signal glasses for railways, chemical porcelain, ceramics components of automobile spark plugs, hot face insulation bricks, selenium-free red glass for bangles, lead and boron free glazes, glasses for glass to metal seals, glass electrodes for pH meters, partial substitution of cobalt oxide in making blue coloured bottles, autoclave plaster of Paris and lithium chemicals from indigenous lepidolite.

It is clear that from making glass for delicate bangles, to glass that could shield from radiation; from dental porcelain to porcelain spark plugs, the newly-created institute straddled many spheres; the linking thread being the motto of service to the nation.

Major economic benefit was reaped by the new nation from the heat insulating bricks made from waste mica that was used to replace imported diatomite product. Indigenous zircon sand was used to make opacifiers for ceramic glazes. The cost of opaque glazes was also reduced to less than one-third by using indigenous opacifiers and reducing the lead content of glaze. This was of immeasurable profit for village potters who made red clay pottery

An outstanding achievement was the development of neodymium-doped laser glass rods which were used to make sophisticated range-finders. CGCRI contributed tremendously towards developing dental porcelain, which was not made in India at that time. The range of specialty glass made by CSIR-CGCRI is large and includes the following.

Atomic radiation shielding glass: Polished and transparent glass with very high lead content that could prevent harmful atomic radiation from passing through it was developed very early in the institute’s history. Over the decades, CSIR-CGCRI has mastered the science behind the making of Radiation Shielding Glass (RSG). It is India’s only indigenous source of RSG.

Infra-red transmitting glass: This is required by the Defence Sector for use in vehicle headlights/searchlights. This glass cuts off visible light but allows invisible heat radiations to pass. It is invaluable to spot the enemy- positions in the dark without revealing one’s own position.

Glasses for glass to metal seals: These glasses were entirely imported till CSIR-CGCRI developed a technology that used nickel–cobalt ferrous alloy (Kovar alloy) and Tungsten to develop an indigenous version.

Foam glass or Multi-cellular glass: This glass is as light as cork and is a very efficient low-temperature thermal insulator. It finds use in the petrochemical and fertilizer industries, cold storage facilities and for thermal insulation of hot/cold pipes etc. Secrecy shrouded its manufacture as countries with know-how guarded information closely. CSIR CGCRI used indigenous materials as well as an in-house production process to develop this type of glass that compares very favourably to international brand names.

Chemically toughened glass: This is a special boron-free alumina-silicate glass, developed by CSIR-CGCRI. It melts at around 1450ºC and has high resistance to thermal shock and chemical attack. It is particularly suitable for making laboratory glassware, ovenware, lantern chimney and other items which are usually subjected to chemical/mechanical and thermal shock during use.

Laser glass: Two-types of Laser-glass viz. Silicate and Phosphate (Neodymium doped) were developed at CSIR-CGCRI for use in the strategic sector.

Bioglasses/Glass-ceramics: Bioglass was one of the first completely synthetic materials that had bio-compatibility and osteogenic capacity. CSIR-CGCRI is one of the few institutes that possesses the technology to produce such glass.

Glass-reinforced Gypsum: CSIR-CGCRI developed Glass-reinforced gypsum to serve as a substitute for wood used in housing projects. This low cost composite material can be used to make doors, windows, furniture, partitions and ceilings; thus lessening the load on swiftly depleting natural resources.

Plasma Display Panel (PDP): This consists of two glass plates separated by a gap of about 130 µm filled with inert gas mixture which can emit UV photons. CSIR-CGCRI was successful in its attempt to develop environment-friendly, cost-effective, lead-free transparent dielectric glass powders and pasted for PDP.

Ultra Low expansion Translucent Glass (ULET): These glasses have almost zero thermal expansion over a wide thermal range and have excellent thermal shock resistance. CSIR-CGCRI has developed technology to make ULET.

The list is a never-ending one. For more detailed information: Science and Technology of Glass and Ceramics – A CSIR Story

Glimpses of the Past

Last Updated on October 31, 2023