English | हिन्दी

সিএসআইআর-কেন্দ্রীয় কাঁচ ও সেরামিক গবেষণা সংস্থা

सीएसआईआर-केंद्रीय काँच एवं सिरामिक अनुसंधान संस्थान

CSIR-Central Glass & Ceramic Research Institute

Advanced Material & Chemical Characterization

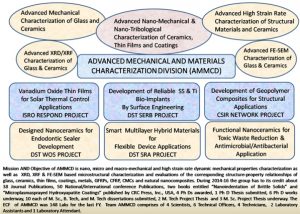

Overview

Areas of Research

Major Activities

- Correlation of microstructural parameters with Flexural strength and Compressive Strength of glass, ceramics and composites at room temperature

- Correlation of microstructural parameters with bonding strength of ceramic coatings at room temperature

- Evaluation of Flexural Strength of Ceramics and Composites by four-point bending up to 1400?C

- Fractography of Ceramics and Composites

- Synthesis and Characterization of Multilayer Ceramic Composites for Damage Tolerant Applications

- Synthesis and Characterization of Ceramic-Polymer Hybrid Composites For Structural Application

- Evaluation of Fracture Toughness of Glass, Advanced Structural Ceramics, Composites, Thin Films and Coatings as well as Natural Nanocomposites by Indentation Fracture Method, SENB Method and SEVNB Method at room temperature

- High Strain Rate Deformation and Fracture of Ceramics

- Shock Physics of Ceramics

- Microindentation Behaviour of Glass and Ceramics

- Scratch induced Deformation and Fracture Behaviour of Glass and Ceramics

- Nanoindentation Response of Glass, Advanced Structural Ceramics, Bio-Ceramics, Composites, Thin Films and Coatings, Energy Ceramics and Sensor Ceramics, Multi-Ferroic Ceramics, Green Ceramics etc.

- Nanotribological behaviour of Glass, Advanced Structural Ceramics, Bio-Ceramics, Composites, Thin Films and Coatings

- Soft Synthesis and Characterization of Thin Films and Coatings

- Soft Synthesis and Characterization of Nanoceramic oxide and hydroxide powders

- Development of Novel Biomedical implants with Enhanced reliability

- Development of clay based geo-polymers for structural applications

- Studies on Vanadium oxide based Thin Films for Spacecraft Thermal Control Applications

- Contact Deformation Mechanisms in Brittle solids

- Synthesis of Calcium based Endodontic Sealer

- Structural, Mechanical and Microstructural Investigation of Glasses and Ceramics by XRD, Mechanical Testing, Scanning Electron Microscopy and Energy Dispersive X-ray (EDX) Analysis

- Nanomechanical Characterization of Human Hair

- Development of ITO based Thin Films for Stealth Application

- Nanomechanical Characterization of carbon/carbon composites

- Qualitative and quantitative phase analysis in materials using X-Ray Diffractometry (XRD) technique

- Crystal structure refinement and structure solution, modeling of structures and evaluation of microstructural parameters like cystallite size, lattice strain, stacking faults (deformation faults and twin faults), dislocation density and cell parameters etc from X-ray diffraction line profile analysis using Rietveld multiphase analysis.

- Development of ferroelectric/piezoelectric and Transition-metal-oxide based Thin Films for Sensors and Transistors.

Technology Developed

The AMMCD Research Group is now working in full swing for possible development of following technologies

- Nanoceramic Oxide/Hydroxide Powders for Removal of Toxic Waste like Cd, Cu, As etc. from Wastewater

- Development of Geopolymer Composites for Reduction of Carbon Footprints

- Nanocrystalline BaTiO3 powder for multifunctional applications, specially as a supercapacitor in electronic industry

- Technological Process for Ceramic Endodontic Sealer for better and less cost intensive health care, especially root canal treatment

- Technological Process for Antibacterial Nanoceramic Agent Development for High efficiency Biocaompatible Applications

- Technological Process for Self-sustainable Thin Film based Smart Window Coatings to reduce electricity consumed for air conditioning

- Damage tolerant, designed multi-layer composites for high strain resistant applications

- Thin Films with Variable Emittance for Spacecraft Thermal control Application

- Smart Nanoceramics for Pb and Zn removal from Wastewater

- Development of Microstructurally Designed Bio-steel Based Cost effective and Reliable Bioimplants

- Development of Surface Engineered Reliable Ti-6Al-4V Alloy Based Bioimplants

Projects

Ongoing Projects

| Sl No | Title of project | Duration | Source of funding | Principal investigator | Co-investigators |

| 1 | Novel Biomedical implants with Enhanced reliability | 2014 – 2017 | DST (SERB) | Dr. A. K. Mukhopadhyay | Dr. J. Ghosh and

Dr. M. Sreemany (AMMCD), Dr. S. Bysakh (AMCU), Dr. V. K. Balla, Dr. B. Kundu, Mr. S. Ganagadharan (BCCD,CSIR-CGCRI), Dr. S. Mukherjee, Mr. R. Rane and Ms. A. Joseph (IPR-Gujarat) |

| 2 | Development of clay based geo-polymers for structural applications | 2012-2017 | CSIR Network Project under 12th Five year Plan | Dr. A. K. Mukhopadhyay | Dr. S. K. Ghosh (TCC, CSIR-CGCRI) |

| 3 | Studies on Vanadium oxide based thin films developed by dip/spin coating techniques for space craft thermal control applications | 2014-2017 | ISRO | Dr. A. K. Mukhopadhyay | Dr. A. Dey and

Dr. N. Sridhara (ISAC, ISRO, Bangalore) |

| 4 | Contact Deformation Mechanisms in Brittle solids | 2014-2016 | CSIR | Ms. M. Bhattacharyay, CSIR-SRF | Dr. A. K. Mukhopadhyay (Scientist-Mentor) |

| 5 | Synthesis of Calcium Based Endodontic Sealer | 2015-2018 | DST | Mrs. N. Biswas, Woman Sct. | Dr. A. K. Mukhopadhyay (Scientist-Mentor) |

| 6 | Structural, Mechanical and Microstructural Investigation of Glasses and Ceramics by XRD, Mechanical Testing, Scanning Electron Microscopy and Energy Dispersive X-ray (EDX) Analysis | 2012-2017 | CSIR-CGCRI (Major Infrastructural Project) | Mr. A. K. Chakraborty | Dr. A. K. Mukhopadhyay,

Dr. J. Ghosh and Dr. M. Sreemany (AMMCD) |

| 7 | Novel Membrane Based Process Technology for Sustainable Energy Devices [part of CERMESA] | 2012-2017 | CSIR Network Project under 12th Five year Plan | Dr. D. Sanyal (PI) and Dr. S. Dasgupta (Work Package Leader) | Dr. M. Sreemany |

| 8 | “Organic-Inorganic Hybrids and other new Materials for Solar Energy Applications”, CSIR-MNRE-TAPSUN | 2012 – 2017 | CSIR | Dr. S. Ugale (Project Co-ordinator. Nodal Lab: NCL Pune) | Dr. P. K. Biswas,

Dr. M. Sreemany, Dr. S. Jana |

| 9 | “Ceramic based Special Electron Tube Components for Large Scale Application” Networked Programme Titled “Design and Fabrication Capabilities for very High Power Microwave Tubes” | 2012 – 2017 | CSIR | Dr. V. K. Balla (Nodal Lab: CEERI Pilani) | Dr. M. Sreemany |

Completed Projects

| Sl No | Title of project | Duration | Source of funding | Principal investigator | Co-investigators |

| 1 | Development of laminated ceramic composites for structural applications | 1999-2002 | DST(SERC) | Dr. A. K. Mukhopadhyay | Dr K. K. Phani and

Dr. H. S. Maiti |

| 2 | Joining of glass pieces by a novel fusion technique | 1998-2001 | DST | Dr K. K. Phani | Dr. A. K. Mukhopadhyay |

| 3 | Microstructural characterization of thermal barrier coating by indentation technique | 2000-2004 | CSIR-FZJ, Germany | Dr K. K. Phani | Dr. A. K. Mukhopadhyay |

| 4 | Nanostructured Multi-Layer Composites for Damage Tolerant Applications | 2002-2007 | CSIR Network Project under 10th Five year Plan | Dr. A. K. Mukhopadhyay | Dr. H. S. Maiti |

| 5 | Near net shape manufacturing of bio-implants and engineering components from advanced ceramics and metals | 2002-2007 | CSIR Network Project under 10th Five year Plan | Dr. D. Basu | Dr. A. K. Mukhopadhyay |

| 6 | Micromechanical Characterization of Hydroxyapatite Coating for Metallic Implants | 2006-2007 to 2009-2010 | DST(SERC) | Dr. D. Basu | Dr. A. K. Mukhopadhyay |

| 7 | Development of Equation of State of Alumina and ZTA ceramics under shock loading | 2007-2010 | BRNS | Dr. A. K. Mukhopadhyay | Dr. S. K. Biswas |

| 8 | Non-oxide ceramic based advance structural materials for Application in Armors | 2007-2012 | CSIR Network Project under 11th Five year Plan | Dr. S. K. Biswas | Dr. A. K. Mukhopadhyay |

| 9 | Technology for Assessment and Refurbishment of Engineering Materials & Components (TAREMAC), Activity II : Minimally Invasive and Miniature Specimen Techniques : Sub-Activity : Indentation Technique for Ceramic Materials | 2007-2012 | CSIR Network Project under 11th Five year Plan | Dr. A. K. Mukhopadhyay | NA |

| 10 | Renovation of Mechanical Testing Facility at CGCRI | 2007-2012 | CSIR Network Project (SIP 0023) under 11th Five year Plan | Dr. A. K. Mukhopadhyay | NA |

| 11 | Development of X-ray scattering tools & techniques for nano-scale investigation in crystalline /amorphous materials | 2011-2013 | CSIR | Dr. S. Majumder / Dr. Jiten Ghosh | Dr. Jiten Ghosh |

| 12 | Residual Quartz estimation by X-ray diffraction technique for commercial production of silica bricks | July 2010 to Sept. 2010 | OCL INDIA LIMITED Rajgang-pur | Dr. Sujata Mazumder | Dr. Jiten Ghosh |

| 13 | Technology Assessment & Refurbishment of Engineering Materials & Components – TAREMAC: NWP 0027 Sub-activity: “Sensors and Sensor Devices Based on Piezoelectric Thin Film” | April 2007 – March 2012 | CSIR Network Project under 11th Five year Plan | Dr. Suchitra Sen | Dr. M. Sreemany |

| 14 | Design and Fabrication Capabilities for Very High Power Microwave Tubes – NWP 0024 Sub-activity 1: “Metallization of AlN surface with Ti by sputtering technique” | April 2007 – March 2012 | CSIR Network Project under 11th Five year Plan | Dr. D. Basu (Project co-ordinator) | Dr. S. Biswas & Dr. M. Sreemany |

| 15 | Custom Tailored Special Materials: CMM 0022 -Task 3 Sub-activity: “Preparation (by R F Sputtering) and Characterization of Nanostructured PZT Thin Films for Electronic and Optoelectronic Applications”. | April 2002 – March 2007 | CSIR Network Project under 10th Five year Plan | Dr. Suchitra Sen | Dr. M. Sreemany |

| 16 | Development of real-time sensors for in-situ monitoring of critical engineering structures based on piezoelectric transduction in thin film: COR 0022 – Task 4 | April 2002 – March 2007 | CSIR Network Project under 10th Five year Plan | Dr. Suchitra Sen | Dr. M. Sreemany |

| 17 | Study on development of rainbow coloured oxide coating on transparent glass substrate using sol-gel process: OLP 060309 | April 2000 – March, 2003 | CSIR | Dr. Suchitra Sen | Dr. M. Sreemany &

Smt. S. Roy |

Divisional Facilities

UTM (INSTRON 5500R), Load Cells:100N (For Fibers and Fibrous Material Testing), 1kN, 100kN; Accuracy:±1%, High Temperature Testing Capability:1400?C with 4-point Bend Fixture |

Hysitron Nanoindenter (Triboindenter Ubi 700, Hysitron Inc., USA) with Nanoindentation, Scanning Probe Microscopy and Nanotribology Facilities; Load Range 1-12,000 micro-N, Depth Resolution:0.04nm, Load Resolution: 1nN. |

|

Split Hopkinson Pressure Bar apparatus (REL Inc. USA) |

||

Fischerscope Nanoindenter (H100XYp, Fischer, Switzerland), Load Range:0.4-1000 mN, Depth Resolution:1 nm, Load Resolution: 0.2micro-N. |

Vicker’s Hardness Tester (LV 700, LECO, USA), Load Range 30 gf to 30Kgf, resolution:0.1micro-m. |

|

Scratch Tester TR-102-M3 (Ducom, Bangalore, India) Load Cells 2-20N, 20-200N, Accuracy ±1%, AE Frequency:100-450 Peak Frequency:450 kHz, Speed variable:100-1000 micro-m.s-1 |

Inverted Optical Microscope (U-LH75XEAPO, Olympus, Japan), Magnification:5-100X, (Reflection and Transmission Mode), Nomraski Interference Contrast, Image Analysis Facility Available |

|

Spin Coater (Model No: 121014, Delta Scientific, Kolkata, India), Maximum RPM-15000 |

Polishing and Grinding Machine, (Struers A/S, Denmark) |

|

Cutting Machine (Struers A/S, Denmark) |

Centrifuge – Max RPM 15000 (Remi, India) |

|

Ultrasonic Cleaner, Takashi, Japan |

Magnetic Stirrer (Remi, Kolkata)-1, IKA RH Digital (Germany)-1 |

|

pH Meter (Systronics, India) |

Sintering Furnace 1: Muffle Furnace, Maximum working temperature (16000C), Max-17000C, Naskar & Co., Kolkata, India |

|

Sintering Furnace 2: Muffle Furnace, Maximum working temperature (13000C), Max-14000C, M/s Jay Crucibles, Kolkata, India |

Sintering Furnace 3: Muffle Furnace, Maximum working temperature (16000C), Max-17000C, M/s Naskar & Co.,, Kolkata, India |

|

Sintering Furnace 4: Tube Furnace, Controlled Atmosphere, Maximum working temperature (5000C), Max-6000C, M/s LabthermIndia Kolkata, India |

Sintering Furnace 5: Muffle Furnace, Maximum working temperature (5000C), Max-10000C, M/s Naskar and Co., Kolkata, India |

|

Polishing and Grinding Machine, (Struers A/S, Denmark |

Semi-Automatic Press (10 Tonnes, Carver, USA) |

|

X’PertPro MPD (PANalytical) Facility |

X-Ray Florescence (XRF) Spectrometer (PANalytical) Facility |

|

HERZOG, Hydraulic Press, TP 20P, Machinenfabrik, Germany |

Planetary Monomill, Pulverisette GmBH, Germany |

|

Field Emission Scanning Electron Microscope, Supra 35 VP, Carl Zeiss, Germany, 30kV, Image Resolution-1.5 nm, Energy Resolution~133 eV |

Field Emission Scanning Electron Microscope, Zigma, Carl Zeiss, Germany, 30kV, Image Resolution-1.3 nm, Energy Resolution~127 eV |

|

Coating Unit (SC7640, QUORUM, UK) |

Coating Unit (Scan Coat 6, Edwards, UK) |

|

Vacuum Evaporator (Hitachi, Japan) |

RF/DC Magnetron Sputter Coater (Hind Hi-VAC, Banaglore, India) |

|

Scientists

- Dr. Jyotirmoy Sikder, Chief Scientist & Head

- Dr. Dipten Bhattacharya, Chief Scientist

- Dr. Prasanta Kumar Sinha , Senior Principal Scientist

- Dr. Nimai Chand Pramanik , Senior Principal Scientist

- Dr. Saikat Deb Acharya, Principal Scientist

Technical/Support Staff

| Name | Designation | Expertise / Capability |

| Srikanta Dalui | Principal Technical Officer | Mechanical Properties |

Ranjan Samaddar |

Senior Technical Officer(1) | Chemical analysis of glass and ceramic materials using ICP-AES and pH-ion meter |

|

Senior Technical Officer(1) Contact: Mob: 08017723375

|

Fabrication of asymmetric tubular hollow fiber Membrane. Designing of high temperature gas permeation setup, Gas permeation studies with ceramic supported Pd membrane. Operation and maintenance of TG-DTA, GC, ISE Instruments and furnaces. |

| Dr. Tanmoy Basak | Technical Assistant | |

| Rohit Kumar Mohanty | Technical Assistant | |

| Deep Kumar Sinha | Technical Assistant | |

| Chittabrata Choudhury | Senior Technician (2) | |

Ajay Kumar Sah |

Technician(2) | Operation of water distillation units, Sample receiving and grinding, Report typing |

| Krishnendu Mondal | Technician (1) |

Scholars/Students

Last Updated on October 1, 2024