English | हिन्दी

সিএসআইআর-কেন্দ্রীয় কাঁচ ও সেরামিক গবেষণা সংস্থা

सीएसआईआर-केंद्रीय काँच एवं सिरामिक अनुसंधान संस्थान

CSIR-Central Glass & Ceramic Research Institute

Dr. Saikat Deb Acharya

Principal Scientist & Associate Professor, Engineering Sciences, AcSIR

Advanced Mechanical and Materials Characterization Division

(High Speed Experimental Mechanics: Split Hopkinson Pressure Bar)

Contact Information:

Phone: +91-33-2322 3247 (Institute), 033-2465 7835 (R)

FAX : +91-33-2473 0957

Mobile: 94335 80935

E-mail: saikat@cgcri.res.in; saikat.acharjee@gmail.com

Dr. Saikat Deb Acharya

Joined CSIR-CGCRI on February, 2001 (Bio-Sketch)Professional Career

| Organization | Designation | Duration |

| CSIR-Central Glass and Ceramic Research Institute, Kolkata (A constituent laboratory of Council of Scientific and Industrial Research (CSIR), Ministry of Science & Technology, Govt. of India) |

Scientist/ AcSIR-Teacher | Feb 2001 – till date |

| Jaya Shree Insulators, Rishra, Howrah (Aditya Birla Group Unit) |

Asst. Manager | Jan 2000 – Dec 2000 |

| Tata Engineering & Locomotive Co. Ltd. (TELCO), Jamshedpur/ Gramophone Co. of India Ltd. (GCIL), Kolkata | GET/ Engineer/ Sr. Engineer | Jul 1992 – Dec 1999 |

Education

| Degree | Discipline | University; Year |

|---|---|---|

| B.E. (Hons.) | Mechanical Engineering | National Institute of Technology Durgapur |

| PGDBM | Indian Institute of Social Welfare & Business Management, Kolkata | |

| Ph.D. | Metallurgical and Materials Engineering | National Institute of Technology, Durgapur |

Research Interest

Materials science and engineering with a special reference to dynamic mechanical behaviour of materials under various loading conditions and states of stresses in high strain rate regime and microstructural characterization for structure property correlation:

- Mechanical Behaviour of Materials

- Dynamic Fracture Mechanics

- Experimental Solid Mechanics

- Rock Mechanics

- Bone Mechanics

Scientific Contribution

- Product Development Specifics of work done by the candidate for excellence

Dr. Acharya has studied the dynamic response of materials (metal, ceramics and polymers) for designing the impact resistance structures. Although, this type of studies is very important for the fabrication of armors but is rarely visible in our country. The excellent part of his study is the determination of structure-property relation during dynamic loading. He had studied the commonly used materials like Al2O3 ceramics, Steel and Polymers commercially available for the development of armors indigenously. The work, therefore, commands engineering excellence in designing composite armor. Some of the key features of his achievements are:

- The observed stress induced subgrain formation in the microstructure of Al2O3 ceramics formed by local barriers to the motion of dislocations by gliding action. As a result, the dislocations are forced to take a bowed configuration (Ref: Ceram. Int. 41 (2015) 6793-6801).

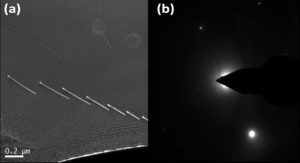

(a) Weak-beam dark-field and, (b) SAD pattern illustrate an array of dislocations of a grain under the diffraction condition.

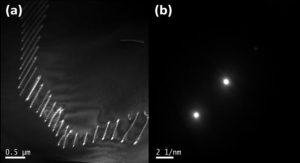

(a) Weak-beam dark-field and, (b) SAD pattern provide evidence for formation of subgrain due to formation of an alumina grain.

- The proposed empirical relations that can predict the compressive yield strength (σyc of PMMA, PC, and GFRP covering a range of eight orders of magnitude in terms of strain rates e.g., from 10-4 – 104 s-1 (Ref: Polym. Bull. 71 (2014) 133-149; Mater. Res. Express 4 (2017) 035303).

- The observation of transgranular cracks and steps in Al6061-T6 alloys during impact deformation when strain rate is increased to 6500 s-1., revealing a relatively ductile mode deformation mechanism. Dynamic fracture mechanism of Al6061-T6 is observed to have changed as strain rates are increased in steps (Ref: Mater. Charact. 127 (2017) 185-197).

- Strain rate induced phase transformation in Austenitic steels e.g., SS304L showing the presence of martensitic plates of length 1mm and thickness 50-100 nm up to the maximum of 12 vol% at strain rate 1800 s-1 in the parent austenitic phase. C and N being strong austenite stabilizer act as deterrents in phase transformation process in SS316LN alloys under impact deformation (Ref: Mech. Mater. 136 (2019) 103073).

Bright field TEM image of SS304L: (a) shows strain induced martensitic structures, (b) substructures within the martensitic grains, and (c) dark field TEM image using a martensite diffraction spot.

All the above achievements refer to excellent and novel knowledge generation in his research.

- Category

Light-weight Composite Integral Vehicular Armor by designing/ integrating ceramics and metal alloys in order to defeat projectiles of level III, NIJ. The effort was appreciated by the Ministry of Defence for the CSIR network project no. NWP0029 [Annexure 1]

- Creation of National Facilities

Commissioning of (i) Split Hopkinson Pressure Bar (SHPB) apparatus, (ii) X-Ray Micro Computed Tomography facility, and (iii) Sintered Ceramic Machining facility at CSIR-CGCRI.

All these facilities are unique for characterization of ceramics and new in the country when procured.

Awards:

- Fellow (FIE), The Institution of Engineers (India), Kolkata, 2020

- Best Project award as Co-PI from CSIR-CGCRI for a Private Sponsored Project, 2014

- Undergraduate Scholarship 1988 (Merit)

- Gandhi Centenary Scholarship 1986 (Merit)

- National Scholarship 1984 (Merit)

Peer Recognition:

- Journals Refereed

- Materials Science & Engineering A, Elsevier

- Polymer Bulletin, Springer

- Metallurgical and Materials Transactions A, Springer

- Ceramics International, Elsevier

- Transaction of the Indian Ceramic Society, Taylor & Francis

- Reviewer of Externally Funded Projects for Government Sponsorship

- CSIR, Ministry of Science and Technology, Govt. of India

- Science and Engineering Research Board (SERB), Dept. of Science and Technology, India

- Membership of Academic and Professional Bodies

- Life Member, Materials Research Society of India (MRSI), India

- Life Member, Electron Microscope Society of India (EMSI), India

- Life Member (Governing Body), Millennium Institute of Energy & Environment (MIME), Kolkata

- Life Member, The Indian Ceramic Society (ICS), India

- University/Institute/Laboratory/Conference visited/invited and talks delivered

- ME Dept., Budge Budge Institute of Technology, Kolkata (Dr. Pallab Roy, HoD, ME), “Properties of Materials and Fracture Mechanics”, in an advanced academic curriculum for undergraduate students of ME: 18 Dec 2020.

- 12th Asia-Pacific Microscopy Conference (APMC 2020) at HICC Hyderabad, “Electron microscopy of SS304L and SS316LN alloys under SHPB tests”, 04 Feb 2020.

- MME NIT Durgapur (Prof. K.S. Ghosh): “High strain rate deformation and failure of a few structural materials”, in TEQUIP Workshop, Mechanical Behaviour and Modeling of Materials (MBMM-2017); 10 Feb 2017.

- MET IIT (BHU) Varanasi (Prof. N.K. Mukhopadhyay): “Electron Microscopy of damage evolution in SHPB tests on Layered Alumina-Polymer composite”, in International Conference on Electron Microscopy (EMSI-2016); 03 Jun 2016.

- Met Colloquium, IGCAR Kalpakkam (Dr. A.K. Bhaduri, Director): “Dynamic Mechanical behaviour of a few structural materials by SHPB”, 02 Feb 2016.

- CSIR-IMMT, Bhubaneswar (Dr. B.B. Jha): “Nanomechanical Properties of AlN-SiC Composites”, at International Conference on emerging materials (ICEMP-2014); 27 Feb 2014.

- VSSC Thiruvananthapuram, Kerala (Dr. B. Santosh): “High strain rate compressive behaviour of GFRP”, in ISAMPE International Conference on Composites (INCCOM)-13); 14 Nov 2014.

- IGCAR Kalpakkam (Dr. B. Purna Chandra Rao), “Dynamic Compressive Fracture of Ceramic Polymer Layered Composites”, in International Conference on Structural Integrity (ICONS-2014); 06 Feb 2014.

- Department of Materials Science and Engineering. Oxford University, U.K.: (Prof. Richard Todd): Discussion meeting on processing of structural ceramics/ Dynamic Characterization of materials/ SHPB design and set up; 14 Mar 2011.

Selected Publications

- Selected publications in International Journals (last 5 years)

- Saikat Acharya*, A. Moitra, S. Bysakh, M. Nanibabu, S.A. Krishanan, C.K. Mukhopadhyay, K.V. Rajkumar, G. sasikala, D.K. Mondal, K.S. Ghosh, B.B. Jha, K. Muraleedharan, “Effect of high strain rate deformation on the properties of SS304L and SS316LN alloys”, Mechanics of Materials 136: 103073 (2019).

- Saikat Acharya*, R.K. Gupta, Jiten Ghosh, Sandip Bysakh, K.S. Ghosh, D.K. Mondal and A. Mukhopadhyay, “High strain rate dynamic compressive behaviour of Al6061-T6 alloys”, Materials Characterization 127: 185-197 (2017).

- Saikat Acharya*, D.K. Mondal, K.S. Ghosh and A.K. Mukhopadhyay, “Mechanical behaviour of glass fibre reinforced composite at varying strain rates”, Materials Research Express 4: 035303 (2017).

- P.S. Das, M. Bhattacharya, D.K. Chanda, S. Dalui, Saikat Acharya et al., “Failure and deformation mechanisms at macro- and nano- scales of alkali activated clay”, Journal of Physics D: Applied Physics 49(23): 235503 (2016).

- Aniruddha Samanta, M. Bhattacharya, S. Dalui, Saikat Acharya et al., “Nanomechanical responses of human hair”, Journal of Mechanical Behaviour of Biomedical Materials 56: 229-248 (2016).

- Saikat Acharya*, S. Bysakh, P. Venkitanarayanan, A.K. Mukhopadhyay, “Deformation and failure of alumina under high strain rate compressive loading”, Ceramics International 41: 6793-6801 (2015).

- Saikat Acharya* and A.K. Mukhopadhyay, “Dynamic Compressive Fracture of Ceramic Polymer Layered Composites”, Procedia Engineering 86: 281-286 (2014).

- Saikat Acharya* and A.K. Mukhopadhyay, “High Strain Rate Compressive Behaviour of PMMA”, Polymer Bulletin 71: 133-149 (2014).

- Selected International and National Conference Proceedings (last 5 years)

- Saikat Acharya*, Sandip Bysakh, and Aniruddha Moitra, “Electron microscopy of SS304L and SS316LN alloys under SHPB tests”, presented at the 12th Asia-Pacific Microscopy Conference (APMC 2020) at HICC Hyderabad; February 3-7, 2020, Souvenir pg-473 Materials Science.

- Saikat Acharya* and Garry L. Messing, “Dynamic deformation of a-alumina with and without texture”, presented at the International Conference organized by the Indian Ceramic Society, Jamshedpur; January 9-10, 2019.

- Saikat Acharya*, Garry L. Messing, K.S. Ghosh, D.K. Mondal, and A.K. Mukhopadhyay, “High strain rate deformation of a-alumina with and without texture” presented at 2nd International Conference on Alumina and Other Functional Ceramics (AOFC-2017) at CSIR-CGCRI, Kolkata; February 15-17, 2017, Abstract book pg-CL05.

- Saikat Acharya*, Manjima Bhattacharya, Sandip Bysakh, K.S. Ghosh, D.K. Mondal, and A.K. Mukhopadhyay, “Electron microscopy of damage evolution in SHPB experiments on layered alumina-polymer composites” presented at International Conference on Electron Microscopy (EMSI-2016) at IIT (BHU), Varanasi; June 2-4, 2016, Abstract book pg-74.

- Saikat Acharya*, M. Nanibabu, A. Moitra, S.A. Krishanan, C.K. Mukhopadyay, K.V. Rajkumar, G. Sasikala, A.K. Mukhopadhyay, K.S. Ghosh, D.K. Mondal, and K. Muraleedharan, “High strain rate deformation behaviour of austenitic steel using SHPB”, presented at National Seminar on Make in India: Challenges for Indian Industries (Mining, Metal and Services), Indian Institute of Metals, Kolkata Chapter; December 17, 2015, Souvenir pg-14.

- Saikat Acharya*, K.S. Ghosh, D.K. Mondal, and A.K. Mukhopadhyay, “Dynamic Mechanical Behaviour of Ceramics and Polymers under high strain rate compressive loading” presented at World Congress on Microscopy: Instrumentations, Techniques and Applications in Life Sciences and Material Sciences (WCM-2015), International Unit on Macromolecular Science and Engineering (IUMSE), Mahatma Gandhi University, Kottayam, Kerala; October 9-11, 2015, Abstract book pg-53.

- Saikat Archarya*, Sandip Bysakh, Venkitanarayanan P., and A.K. Mukhopadhyay, “High Strain Rate Dynamic Failure Mechanism of Alumina ”, presented at 1st International Conference in Alumina and Other Functional Ceramics (AOFC-2015) at CSIR-CGCRI, Kolkata; March 11-13, 2015, Abstract book pg-61.

- Saikat Acharya* and A.K. Mukhopadhyay, “High strain rate compressive behaviour of GFRP and PMMA”, presented at 1st International Conference on Emerging Materials: Characterization and Application (EMCA-2014), at CSIR-CGCRI, Kolkata; December 04-06, 2014, Conference Proceedings pg-125.

- R. Sharma, S. Das, A.K. Mukhopadhyay, and Saikat Acharya*, “The strain rate dependence of dynamic impact properties of 6061-Aluminium Alloy”, presented at 1st International Conference on Emerging Materials: Characterization and Application (EMCA-2014) at CSIR-CGCRI, Kolkata; December 04-06, 2014, Abstract book pg-124.

- Saikat Acharya* and A.K. Mukhopadhyay, “High Strain Rate Compressive Behaviour of GFRP”, presented at ISAMPE National Conference on Composites (INCCOM-13) at Vikram Sarabhai Space Centre, Thiruvananthapuram; November 14 – 15, 2014, Abstract book pg-44.

- Saikat Acharya*, M. Bhattacharya, S. Basu, and A.K. Mukhopadhyay, “Nanomechanical Properties of AlN-SiC Composites”, presented at International Conference on Emerging Materials and Processes (ICEMP-2014) at CSIR-IMMT, Bhubaneswar; February 26-28, 2014, Conference Proceedings pg:430-435.

- Saikat Acharya* and A.K. Mukhopadhyay, “Dynamic Compressive Fracture of Ceramic Polymer Layered Composites”, presented at International Conference on Structural Integrity (ICONS-2014) at IGCAR, Kalpakkam; February 4-7, 2014, Abstract book pg-67.

- Publications of Book/ Book Chapters:

- Saikat Acharya*, K.S. Ghosh, D.K. Mondal, and A. Mukhopadhyay, “Design issues in high strain rate dynamic compressive failure of structural ceramics, polymers and composites”, Editors: Ajay Vasudeo Rane, Sabu Thomas, Nandakumar Kalarikkal, Krishnan Kanny, “MICROSCOPY APPLIED TO MATERIAL SCIENCES AND LIFE SCIENCES”, Apple Academic Press, CRC Press, Taylor & Francis Group, 2018, Chapter 9.

- “Nanoindentation of Brittle Solids”, Section 12: Chapters 46, 47, and 48; CRC Press, Taylor & Francis Group, Jun 2014.

* Corresponding author

Academic Contribution

|

|

Institution/ University |

Area of specialization |

|

Associate Professor |

Academy of Scientific & Innovative Research (AcSIR)/ CGCRI Kolkata |

Engineering Sciences (Fracture Mechanics and Mechanical Characterization) |

|

Resource Person |

Laboratory for Innovation Science, Harvard University |

They wanted research findings for evaluating and ranking scientific works, and possibly develop superior alternatives. |

|

Hopkins Extreme Materials Institute, USA |

They wanted experimental data related to Al6061-T6 alloys to be available with their repository for broader research community. |

|

|

Sidho-Kanho-Birsha University, Purulia

|

To facilitate i) Nano-mechanical Characterization Lab, and ii) Processing of Nano-Materials |

|

|

Guest Lecturer |

i) IIT BHU, Varanasi

ii) NIT Durgapur

iii) Budge Budge Institute of Technology, Kolkata |

i) Materials Behaviour under High Strain Rate (HSR) Loadings ii) Mechanical Behaviour and Modeling of Materials iii) Properties of materials and Fracture Mechanics |