English | हिन्दी

সিএসআইআর-কেন্দ্রীয় কাঁচ ও সেরামিক গবেষণা সংস্থা

सीएसआईआर-केंद्रीय काँच एवं सिरामिक अनुसंधान संस्थान

CSIR-Central Glass & Ceramic Research Institute

Non-Oxide Ceramics & Composites

Overview

CGCRI is the pioneer in research on non-oxide ceramics in India and has the cutting edge in this field. The materials dealt with are silicon nitride, SiAlONs, AlON, aluminum nitride, silicon carbide and composites with carbon fiber and CNT having an aim to use the materials in low and high temperature structural applications. The products developed are dense silicon nitride ball for hybrid bearing and other wear resistant components, aluminum nitride as impact resistant material, AlON for visible and IR transparent windows, reaction bonded silicon nitride porous tube for acid electrolysis, hexagonal boron nitride powder for high temperature lubrication. Present work includes both basic research and product development on multi-layer composite, carbon fiber reinforced wear resistant auto clutch component, hard SiAlON cutting tools, bio-mimetic silicon carbide high temperature filter. The division also possesses equipment for room temperature and high temperature mechanical property evaluation at macro- to micro-levels. Correlation of material-microstructure-property is the other area of research of the division.

Areas of Research

- Reaction bonded silicon nitride

- Reaction bonded silicon carbide

- Dense silicon nitride

- Carbon fibre reinforced silicon carbide

- CNT reinforced structural ceramic composites

- Porous Silicon Carbide Ceramics and Composites

- Biomorphic Silicon Carbide Ceramic Composites

- High temperature gas filtration

- Mechanical behaviour at very high strain rate

- Ultra high temperature ceramics

Technology Developed

- Dense silicon nitride and sialon wear resistant components

- Reaction bonded silicon nitride components

- Hexagonal boron nitride powder

- Dense reaction bonded silicon carbide composite materials (covered by : Indian Patent, 226270, 16 December, 2008)

- Carbon fibre reinforced silicon carbide components

- Biomorphic SiC ceramic composite materials

- Porous SiC ceramics

- SiSiC ceramic composite using processed bio-precursors

Projects

Ongoing Projects

| Sl. No. | Title of the Project | Duration | Source of Funding | Principal Investigator | Co-Investigator (s) |

| 1 | Cleaning of hot gas from high ash containing low grade Indian Coal | 2012-17 | CSIR | Nijhuma Kayal | O.P. Chakrabarti |

| 2 | Synthesis of oxide bonded porous SiC ceramics by bond phase precursor infiltration technique | 2013-16 | DST | Nijhuma Kayal | O.P. Chakrabarti |

| 3 | Hot pressing and study of thermo-mechanical behaviour of UHTC samples for aerospace applications | 2013-15 | DRDO | S. Chakraborty | P. K. Das |

| 4 | Development and characterization of Silicon Carbide foam | 2014-16 | DRDO | S. Sarkar | P. K. Das S. Chakraborty |

| 5 | Non oxide ultra high temperature ceramic components | 2012-17 | CSIR | P. K. Das | S. Chakraborty |

| 6 | M-AlON based IR transparent window | 2012-17 | CSIR | S Bondopadhyay |

Completed Projects

| Sl. No. | Title of the Project | Duration | Source of Funding | Principal Investigator | Co-Investigator (s) |

| 1 | Porous RBSN diaphragm tube | 2006-10 | Govt. | P.K. Das | J. Rakshit |

| 2 | RBSN microwave transparent material | 2009-10 | Govt | P.K. Das | J. Rakshit |

| 3 | C-fibre reinforced clutch component | 2008-11 | CSIR | P.K. Das | D.K. Bhattacharya |

| 4 | RBSN leading edge for very high temperature application | 2010-11 | Govt. | P.K. Das | R. Banerjee |

| 5 | Equation of State of Alumina and ZTA ceramics under shock loading | 2007-10 | Govt. | A. K. Mukhopadhyay | Dr. S. K. Biswas |

| 6 | Development of cellular SiC ceramics using biologically derived perform | 2002-2007 | CSIR | O.P.Chakrabarti | — |

| 7 | Cellular SiC ceramics from plant precursor for engineering applications, | 2005-2008 | DST, Govt. of India | O.P.Chakrabarti | H.S.Maiti & R.Majumder |

| 8 | Synthesis of novel composite materials using coir fibre for engineering applications | 2010-13 | CSIR | O.P.Chakrabarti | |

| 9 | Development of porous SiC substrate for hot gas filter applications | 2007-12 | CSIR | O.P.Chakrabarti | N.Kayal, T.Goswami & P.G.Rao |

| 10 | Fabrication Si3N4 ball for hybrid ball bearing | 2010-12 | Govt. | P.K. Das | R. Banerjee |

| 11 | Fabrication of SiC large plates from organic precursors | 2011-12 | Govt. | P.K. Das | R. Banerjee |

Divisional Facilities

FTIR |

Sputter Coating unit |

Vacuum Oven for inflammable Solvent |

Thermal Diffusivity measuring instrument |

Spark Plasma Sintering Furnace |

Hot Isostatic Press |

High Temperature (2000oC) Brazing Furnace with Tungsten Heating Element |

|

SCHAUBLIN, 225 TMI-CNC turning machine |

|

VF-1 HASS VMC (Vertical Milling Machine) |

|

Zeta Sizer |

Particle Size Analyzer |

1500 W Ultrasonic Unit |

Rheometer |

Attritor |

|

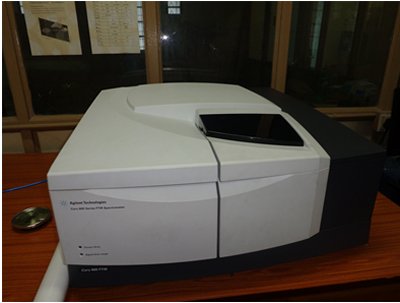

UV Spectrometre |

Non Contact Profilometre |

Flurimetre |

Inverted Optical Microscope with CCD camera with Image Analyzer |

Humidity controlled drier |

High temperature controlled atmosphere furnaces (2000OC) |

High speed Centrifuge of M/S Remi(Max RPM=20000, RCF 37570) 4×100 ml angle head |

Planetary mill (1600 watt) |

Hi temperature electrically heated furnace of chamber size 200mm×200mm×200mm max temp 1800oC |

100 Watts Ultrasonic processor |

Ceramic ball lapping machine |

Micro hardness tester (2 kg) |

Contact type surface profilometer |

High temperature Hot Press (2200C, 40 Ton) |

Precision Surface Grinding Machine |

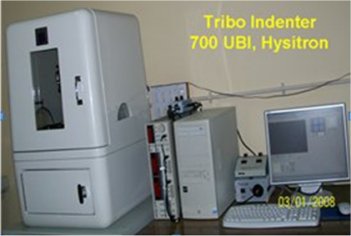

Triboindenter (Nanoindenter with in-situ SPM facility) |

Fischerscope (Nanoindenter with Optical facility) |

Scratch Tester |

Hardness Tester (Vicker’’s and Knoop tip) |

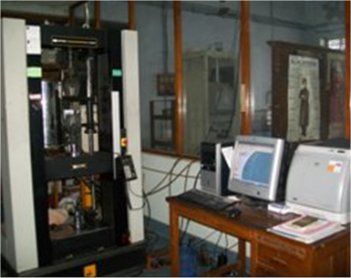

Fully Automated Universal Testing Machine (1 KN, 100 KN, 100 N load cells) |

Scientists

NOCCD family

Name of the Scientists

- Dr. Dipayan Sanyal, Head

- Dr. Omprakash Chakrabarti

- Dr. Tarun K. Kayal

- Mr. Krishnendu Adhikary

- Mr. Ajitesh Kar

- Mr. S. Gangadharan

Technical/Support Staff

| Name | Designation | Expertise |

| Dr. Rajat Banerjee | Sr. Tech. Officer(3) | Fracture of Glass, Computational analysis |

| Sandip Chakraborty | Sr. Tech. Officer(1) | Glass & Ceramic Characterization |

| Pranab Pal | Technical Officer | Ceramic Machining and NDT |

| Sumantra Basu | Technical Officer | Instrumentation |

| Ramprasad Mondal | Technical Officer | Ceramic Machining and NDT |

| Subhendu B. Mondal | Technician (2) | Instrumentation |

| Naresh Kumar Oraon | Technician (2) | Ceramic finishing |

| Subhankar Bera | Tech. I | Furnace Operation |

| Taraknath Ojha | Lab. Asst. | General assistance |

| Gopal Ch. Das | Sr. Technician(2) | |

| Chhoton Kerketta | Sr. Technician(3) | |

| Debashish Bhattacharjee | Sr. Technician(2) | |

Mr. Sanjiban Das |

Technician(2) | |

Mr. Samir Kumar Kopai |

Technician (1) |

Scholars/Students

| Name | Status | Project | Paper(s) Published [Best Five] |

Supervisor |

| Azizur Rahaman Mallick | Project Fellow | Advanced ceramic materials & components for energy & structural applications | P. K. Das | |

| Jonaki Mukherjee | Senior Research Fellow | Deposition and characterization of SiC coating on Si | Dr. Rajat Banerjee | |

| Atanu Dey | Senior Project Fellow | CSIR-CERMESA (SiC Hot Gas Filter) | Dr. O.P.Chakrabarti | |

| Anwesha Maity | Senior Research Fellow (CSIR) | Reaction processing of SiC ceramics using plant precursor | Dr. O.P.Chakrabarti | |

| SANCHITA BAITALIK | JRF | |||

| Kaushik Sarkar | Project Fellow |

Contact

Coming soon

Last Updated on July 23, 2019