English | हिन्दी

সিএসআইআর-কেন্দ্রীয় কাঁচ ও সেরামিক গবেষণা সংস্থা

सीएसआईआर-केंद्रीय काँच एवं सिरामिक अनुसंधान संस्थान

CSIR-Central Glass & Ceramic Research Institute

"Innovation in Ceramics and Glass for the mankind"

Membrane and Separation Technology

Overview

India is one of the largest expanding economies having high future potential. The high economic and population growth rates are accompanied by an increase in the standard of living and a huge rise of energy and water demand as well as soaring emissions of greenhouse gases such as CO2. Much of this economic and corresponding social development is expected to take place in rural areas. In consequence, provision of clean and sustainable water to the rural population becomes increasingly crucial. At the same time it is crucial that this water is produced by environmentally friendly methods, e.g. using renewable energy resources and energy-efficient technologies. Rural India has more than 800 million people residing in about 1.42 million habitations spread over 15 diverse ecological regions. Groundwater is the major source of water in India with 85% of the population dependent on it. The health burden of poor water quality is enormous. It is estimated that around 37.7 million Indians are affected by water borne diseases annually, 1.5 million children are estimated to die of diarrhoea alone and 73 million working days are lost due to waterborne diseases each year. The resulting economic burden is estimated at $ 600 million a year(Reference : Drinking water quality in rural India: issues and approaches, https://washmatters.wateraid.org). Hence in India access to safe water is regarded as the primary factor responsible for limiting development. The average availability of water is reducing steadily with the growing population and it is estimated that by 2020 India will become a water stressed nation. Therefore the improvement and extension of water treatment remains an important and necessary objective of the Indian government. In addition, volume and the quality of industrial effluents in India is a matter of serious concern. There is a growing need for low footprint and energy efficient technologies for effluent treatment aiming at zero liquid discharge.

Membrane and Separation Technology Division is mandated to contribute significantly in research and development leading to practical application (Lab to land) in the field of water treatment, wastewater treatment, gas separation, green energy, recycling and reuse with special emphasis in development of new generation ceramic membranes and ceramic polymer composite membranes leading to application of such membranes for water treatment, wastewater treatment and reuse.

• Superhydrophobic membrane development (contact angle >1500) on ceramic support for multifaceted applications such as, CO2 capture, oil refinery waste treatment, downstream processing of biofuel and emerging contaminants remediation

• Sustainable recycling strategy for textile fabric waste derived biochar in emerging contaminants remediation and immobilization of the spent adsorbent as efficient electrode material for green energy storage device

Areas of Research

- Ceramic monolithic porous support development

- Ceramic microfiltration membrane

- Ceramic ultrafiltration membrane

- Ceramic polymer composite membrane

- Hydrophobic membranes

- Arsenic remediation from groundwater

- Iron remediation from groundwater

- Surface water pre-treatment

- Adosrbent development

- Industrial wastewater Treatment

- Membrane bioreactor

- Algae based wastewater treatment

- Biomass and biofuel

- Fruit juice clarification

- Water recycle and reuse

- Heavy metal remediation

- Sludge management

- Dust Filtration

- Clean Energy Application (Metallic & Zeolytic membranes for mixture gas separation)

- CO2 Sequestration (Enrichment of flue gas & lean gas)

- Membrane distillation

Technology Developed

| Title | Recipient |

| Ceramic membrane based high capacity modules for pretreatment of turbid water for polishing of iron & arsenic contaminated water using micro filtration technique | 1. Porel Dass Water & Effluent Control Pvt. Ltd., Kolkata on 11.05.2011 2. Sarvo Technologies Limited, Faridabad on 30.8.2017 |

| Ceramic Membrane based Technology for Arsenic & Iron Removal from Groundwater | 1. Entech Metals Pvt. Ltd., Kolkata on 23/04/03 2. Entech Metals Pvt. Ltd. on 22/07/13 3. Victor Engineering Co., Assam on 7.10.2015 4. Porel Dass Water & Effluent Control Pvt. Ltd., Kolkata on 24.04.2015 5. Zeolite (India) Pvt. Ltd. on 11.9.2017 6. Rollabss Hi Tech Industries, on 27.03.2018 |

Projects

|

ONGOING PROJECTS |

|||||

|

S. No. |

Title of the Project |

Project No. |

Duration |

Funding Agency |

Project PI & Co-PI |

|

1. |

Development of a ceramic membrane integrated fermentative reactor process for the production and enrichment of biohydrogen from organic waste |

GAP0391 |

12.03.2024 To 11.03.2027 |

DST |

PI: Dr. Sourja Ghosh Co-PI: Dr. Ganesh Chandra Sahoo |

|

2. |

Monitoring and removal of antibiotics from wastewater by membrane separation Drug-Free Wastewater |

GAP0389 |

14.07.2023 To 13.07.2026 |

DST |

PI: Mr. Swachchha Majumdar Co-PI: Dr. Sourja Ghosh |

|

3. |

Designing Flow-Electrode Capacitive Deionization Cells (FECDC): “Lithium” Recovery from Sea Water and Lithiated Ore |

IHP240008 |

April 2024 To March 2026 |

CSIR |

PI: Vignesh M Co-PI: Mr. Swachchha Majumdar Co-PI: Dr. Mir Wasim Raja |

|

4. |

Ceramic membrane base re-refining of waste engine oil. |

HCP0054 (WP 20) |

28.08.2023 To 31.03.2026 |

CSIR |

PI: Dr. Mahesh Kumar Gagrai Co-PI: Dr. Vignesh M Co-PI: Dr. G.C. Sahoo |

|

5. |

Technology demonstration for utilizing textile/jute industrial wastes into value-added product generation for rubber products manufacturing industries and agricultural sectors using a sustainable approach. |

HCP0054 (WP 28) |

28.08.2023 To 31.03.2026 |

CSIR |

PI: Dr. Sourja Ghosh Co-PI: Mr. Swachchha Majumdar |

|

6. |

Biochar based nanocomposite synthesis from industrial waste for dual application: environment friendly remediation of emerging contaminants and pathogens from wastewater and antimicrobial antiviral surface coating development on medical devices |

GAP 0388 |

21.08.2023 to 20.08.2026 |

DST |

PI: Dr. Lata Ramrakhiani Co-PI: Mr. Swachchha Majumdar Mentor: Dr. Sourja Ghosh |

|

7. |

Development of catalytic membrane reactor for CO2 capture with production of Hz through water-gas shift reaction |

HCP 48 |

April 28, 2023 to March 31, 2026 |

CSIR |

PI: Dr. Nandini Das Co-PI: Dr. Nijhuma Kayal Co-PI: Dr. Mahesh Gagrai |

|

8. |

CSIR Integrated Skill Initiative, Activity: Skill development training on ceramic membrane and water technologies. |

NWP 100 |

December 2020 to November 2025 |

CSIR |

PI: Dr. P.K. Sinha Activity Co-Ordinator: Sri Swachchha Majumdar Activity Leader: Dr. Ganesh Chandra Sahoo |

|

9. |

Phenome India-CSIR Health cohort Knowledgebase |

HCP 47 |

03.08.2022 – 02.08. 2027 |

CSIR |

PI: Sri Swachchha Majumdar Co-PI: Dr. Sourja Ghosh

|

|

COMPLETED PROJECTS |

|||||

|

S. No. |

Title of the Project |

Project No. |

Duration |

Funding agency |

Project PI & Co-PI |

|

1. |

Development of ceramic oxide-based nanofiltration membranes onto oxide-bonded porous SiC supports and their performance evaluation study for liquid, gas and particulate separation |

GAP0380 |

09.03.2022 to 08.03.2025 |

Science & Engineering Research Board (SERB) |

PI: Dr. Nijhuma Kayal Co-PI: Dr. Mahesh Kumar Gagrai |

|

2. |

Feasibility studies of Purification of olefin from C3 olefin-paraffin mixture by Molecular sieve-based Hybrid Process |

GAP 0384 |

03.02.2023 to 02.02.2025 |

Science & Engineering Research Board (SERB) |

PI: Dr. Nandini Das Co-PI: Dr. Nijhuma Kayal

|

|

3. |

Natural Biopolymer based Novel Electrospun and Ceramic Composite membranes for treatment of Wastewater. (Collaborative Project with CSIR-NEIST and CSIR-IICT) |

MLP 1021 at CSIR-NEIST |

February 2022 to February 2025 |

CSIR |

PI: Dr. Ganesh Chandra Sahoo Co-PI: Swachchha Majumdar |

|

4. |

Coal Derived Syngas for Green Energy. (Collaborative project with CSIR-CIMFR)

|

MLP0310 |

25.05.2022 – 24.05.2024 |

CSIR |

Dr. Dr. Nandini Das, Project Nodal

|

|

5. |

WP1: Enrichment of hydrogen from syngas

|

Dr. Nandini Das, PI, WP1 Dr. Mahesh Kumar Gagrai, Co-PI Dr. Nijhuma Kayal, Co-PI |

|||

|

6. |

WP2: Coal Derived Syngas as a Fuel for Solid Oxide Fuel Cell (SOFC) |

Dr. Jayanta Mukhopadhyay, PI, WP2 Dr. Srabanti Ghosh, Co-PI Dr. A. Amarnath Reddy, Co-PI

|

|||

|

7. |

Nano-selective, bio-mimetic membranes for integrated biotechnological production of biofuels from lignocellulosic biomass |

GAP0377 |

1st March, 2021 to 29th February 2024

|

DST, Govt. Of India |

PI: Sri Swachchha Majumdar

Co-PI: Dr. Ganesh Chandra Sahoo

Co-PI: Dr. Sourja Ghosh

|

|

8. |

“Utilisation of toxic wastes as potential sources of colouring ingredient in glass Making(Jointly with Speciality Glass Technology Division of CISR-CGCRI) |

GAP 0179 |

30th December, 2020 to 29th December, 2023 |

Science & Engineering Research Board(SERB) |

PI: Dr. Asish Kumar Mandal (Of SGT Division)

Co-PI: Dr. Sourja Ghosh Project Advisor: Sri Swachchha Majumdar

|

|

9. |

Development and performance characterization of crosslinked beta-cyclodextrin polymer based thin-film composite nanofiltration ceramic membrane (Jointly with FMD Division of CSIR-CGCRI) |

GAP0266 |

30th December, 2020 to 29th December, 2023

|

Science & Engineering Research Board(SERB) |

PI: Dr. Arnab Mukherjee (of FMD Division) Co-PI: Dr. Ganesh Chandra Sahoo Co-PI: Dr. Priyanka Mondal

|

|

10. |

Development of ceramic membranes with internationally competitive specifications and setting up of a pre-pilot plant manufacturing plant facility to promote their application in different separation technologies |

GAP 0354 |

May, 2016 to May 31, 2021 |

DST, Govt. of India |

PI: Sri Swachchha Majumdar CO PI: Dr. Ganesh C Sahoo |

|

11. |

Supply and installation of 51 numbers Iron & Arsenic Removal plant at Border outpost in North 24 Parganas |

TSP 0302 |

December, 2016 to August, 2020 |

PHED, Govt. of West Bengal |

PI: Sri Swachchha Majumdar |

|

12. |

Supply and installation of 43 Nos. Iron & Arsenic Removal plant at Border Out posts in Nadia District. |

TSP 0301 |

April, 2015 to June, 2021 |

PHED, Govt. of West Bengal |

PI: Sri Swachchha Majumdar |

|

13. |

Development of ceramic membrane based process for treatment and recycling of textile effluent towards zero discharge concepts. |

GAP 0356 |

September, 2016 to September, 2020 |

DST, Govt. of India |

PI: Sourja Ghosh CO PI: Sri Swachchha Majumdar |

|

14. |

Water quality management and data analysis report generation for water drawn from river Ganga for proposed Godda Thermal Power Station [2X800 MW) |

TSP 0303 |

June, 2018 to December, 2018 |

Academy of Water Technology and Environ Management, Kolkata |

PI : Sri Swachchha Majumdar

|

|

15. |

Development of Technology for separation of Acetic acid from Effluent generated during the production of HMX |

GAP 0363 |

August, 2017 to April, 2019

|

TBRL, Chandigarh(DRDO) |

PI : Sri Swachchha Majumdar CO PI : Dr. Sourja Ghosh |

|

16. |

Development of surface modification adsorbents with higher sorption capacity for specific contaminants removal in water / industrial wastewater(SMA) (FBR) |

MLP0304 |

August, 2018 to March, 2020 |

CSIR, Govt. of India |

PI: Sri Swachchha Majumdar CO PI: Dr. Sourja Ghosh |

|

17. |

Technology assessment and integration of CSIR’s lignocellulosic ethanol programs/ facilitating technologies for a feasible 2G ethanol technology |

MLP 0305 |

October 2018 to March, 2020 |

CSIR, Govt. of India |

PI: Sri Swachchha Majumdar CO PI: Dr. Ganesh C Sahoo Co_PI: Dr. Sourja Ghosh |

|

18. |

Membrane Contactors for As(III) to As(V) conversion |

CSIR –CNR bilateral |

January 2009 to December, 2011 |

CSIR, Govt. of India |

PI: Swachchha Majumdar |

|

19. |

Upscaling of pilot plant demonstration of ceramic membrane based iron removal plants in West Bengal |

GAP 0316 |

August 2004 to March 2009 |

DST, Govt. of India |

PI: Dr. Sibdas Bandyopadhyay Co-PI: Sri T.K. Ghoshal |

|

20. |

Ceramics Materials for Emerging Technologies involving Liquid and Gas Separation Task 2: Development of industrial waste water purification technology based on ultra filtration membrane developed as above |

SIP-23 |

April 2007 to March 2013 |

CSIR Supra Institutional Project |

Task Leader: Sri Swachchha Majumdar |

|

21. |

Development of layered SiC ceramic filter for off-gas cleaning |

GAP0261 |

23rd March, 2018 to 22nd August, 2021 |

DST-SERB |

PI: Dr. Nijhuma Kayal

|

|

22. |

Oil & Water separation unit for Great Eastern Energy Corporation Ltd. |

TSP 0304 |

31st December, 2020 to 31st October, 2021 |

Prism Johnson Limited |

PI: Sri Swachchha Majumdar |

|

23. |

Process development for tannery wastewater treatment involving membrane bioreactor (MBR) process integrated with micro-algal bioremediation. |

GAP 0362 |

June, 2017 to 30th September, 2021 |

DBT, Govt. of India |

PI: Dr. Sourja Ghosh CO PI: Sri Swachchha Majumdar |

|

24. |

Development of Nanoadsorbents with higher sorption capacity for removal of Fluoride and Arsenic from Groundwater for potential application is water treatment plants. |

SSP 0315 |

24.08.2020 to 23.02.2022 |

Zeolite (India) Pvt. Ltd |

PI: Sri Swachchha Majumdar Co-PI: Dr. Ganesh C. Sahoo |

|

25. |

An integrated technology development involving biosorption for treatment of toxic metal containing wastewater generated from small scale industries and sludge management towards safe disposal. |

GAP 0367 |

August, 2018 to February, 2022 |

DST-WOS-B Scheme |

PI : Dr. Lata Ramrakhiani Mentor: Dr. Sourja Ghosh |

|

26. |

Feasibility studies of enrichment of Ozone in permeate stream and recycling of retentate to the Ozone generator using ceramic membranes |

TSP305 |

22.12.21 to 21.7.22

|

ORAIPL |

PI: Sri Swachchha Majumdar Co-PI: Sri Somjyoti Basak |

|

27. |

Membrane based prototype development for higher yield of microalgal biomass and biofuel using industrial waste resources(International collaborative Project with USA) |

GAP0372 |

August 2019 to August 2022 |

DBT Govt. of India |

PI: Dr. Sourja Ghosh Co-PI: Sri Swachchha Majumdar

|

|

28. |

Next generation high performance in situ generated nano particles embedded sustainable antifouling ceramic-polymer composite NF membranes: preparations, modifications and application aimed at water/drinking water treatment. |

GAP0369 |

March, 2019 to March, 2022 |

Science & Engineering Research Board(SERB) |

PI: Dr. Priyanka Mondal Co-PI: Sri Swachchha Majumdar Co-PI: Dr. Mahesh K. Gagrai |

|

29. |

Synthesis of ceramic-polymer composite membrane: a novel next generation technique for water/ wastewater treatment and pervaparation application |

GAP 0358 |

January, 2017 to November, 2022 |

DST |

PI: Dr. Priyanka Mandal |

|

30. |

Demonstration of ceramic membrane based process for removal of hydrocarbon from contaminated tube well in Hingalganj, Sundarban, West Bengal. |

GAP 0370 |

May, 2019 to May , 2022 |

WSSO, PHED, Govt. of West Bengal |

PI: Sri Swachchha Majumdar Co-PI: Dr. Sourja Ghosh Co-PI: Dr. Ganesh C. Sahoo |

Divisional Facilities

List of the testing facilities at Water Technology Division:

| Sl No. | Nature of the Sample | Testing parameters |

| 1 | Water and Wastewater | Turbidity |

| pH | ||

| Total Dissolved Solid(TDS) | ||

| Conductivity | ||

| Salinity | ||

| Total Suspended Solid (TSS) | ||

| Total Iron | ||

| Total Arsenic | ||

| Total Organic Carbon (TOC) | ||

| Total Kjeldahl Nitrogen (TKN) | ||

| Anions : Fluoride, Chloride, Bromide, Nitrate, Phosphate, Sulfate | ||

| Cations: Lithium, Sodium, Potassium, Calcium, Magnesium, Nickel, Zinc, Cobalt, Cadmium | ||

| Chemical Oxygen Demand (COD) | ||

| Biological Oxygen Demand (BOD) | ||

| MPN (Total coliform) | ||

| Oil & Grease | ||

| 2 | Ceramic Membrane | Pore size Distribution |

Analytical Facilities at Water Technology Division:

Ultra-Fast Liquid Chromatography (UFLC)

| Name of the Instrument | Ultra Fast Liquid Chromatography (UFLC) |

| Specification | Determination of Pesticides, pharmaceutical components and personal care product of liquid sample |

| Model & Make | Shimadza Corporation, Japan |

Zeta Sizer Analyzer (Nano series)

| Name of the Instrument | Zeta Sizer Analyzer ( Nano series) |

| Specification | Analysis of particles size 1µm-1nm in aqueous & non aqueous medium |

| Model & Make | ZEN1600, Malvern, UK |

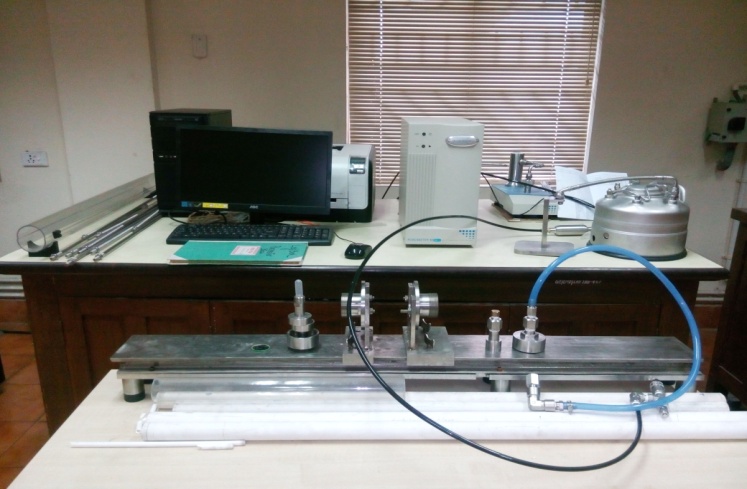

Pore Size Analyzer

| Name of the Instrument | Pore Size Analyzer |

| Specification | Analysis of MF range of pore size for single and multi channel membranes upto 1 meter length |

| Model & Make | Porometer 3G , Quantachrom, USA |

Zeta Potential Analyzer

| Name of the Instrument | Zeta Potential Analyzer (Z series) |

| Specification | Zeta potential of stable suspension of nano particles in aqueous medium |

| Model & Make | ZEN2600, Malvern, UK |

Optical Microscope

| Name of the Instrument | Optical Microscope |

| Specification | Magnification upto 100X |

| Model & Make | STM6, Olympus, Japan |

Polarimeter

| Name of the Instrument | Polarimeter |

| Specification | ± 89.9 degree Arc optical rotation, Std. wavelength 589nm & 880nm |

| Model & Make | Rudolph Research Analytical, USA |

Refractometer

| Name of the Instrument | Refractometer |

| Specification | Measure the refractive index and concentration of liquids |

| Model & Make | Anton Paar GmbH, Austria |

Gas Chromatography

| Name of the Instrument | Gas Chromatography (GC) |

| Specification | Analysis of Ethanol, Bio-diesel, Pesticide, Nitrogen and Phosphorus |

| Model & Make | Dani, Italy |

Ion Chromatography

| Name of the Instrument | Ion Chromatography (IC) |

| Specification | Elemental analysis of Anions (F, Cl, Br, NO3, PO4, SO4 Cation (Li, Na, K, Ca, Mg) T-metals (Ni, Zn, Co, Cd) & Pesticide(Atrazine) of liquid sample. |

| Model & Make | Metrohm, Switzerland |

Total Organic Carbon Analyzer

| Name of the Instruments | Total Organic carbon Analyzer |

| Specification | Analysis of total organic carbon of liquid sample. |

| Model & Make | Shimadza Corporation, Japan |

Spectrophotometer

| Name of the Instrument | Spectrophotometer |

| Specification | Measure the concentration of solutes in solution by measuring the amount of the light that is absorbed by the solution in a cuvette placed in the spectrophotometer. |

| Model & Make | Carry60, Agilent Technologies, India |

Total Kjeldahl Nitrogen (TKN)

| Name of the Instrument | Total Kjeldahl Nitrogen (TKN) |

| Specification | Quantitative determination of nitrogen contained in organic substances plus the nitrogen contained in the inorganic compounds ammonia and ammonium of liquid sample. |

| Model & Make | Pelican Equipment, India |

Scientists

Mr. Swachchha Majumdar, Chief Scientist and Head

Dr. Sourja Ghosh, Senior Principal Scientist

Dr. Nijhuma Kayal, Senior Principal Scientist

Dr. Ganesh C. Sahoo, Senior Principal Scientist

Dr. Mahesh Kumar Gagrai, Principal Scientist

Dr. Vignesh M, Scientist

Dr. Rajan Biswas, Scientist

Others

Dr. Lata Ramrakhiani, DST-Women Scientist (DST-WOS A)

Technical/Support Staff

|

Name |

Designation |

Expertise |

|

Subhendu Sarkar |

Senior Technical Officer (2) |

Standardization & performance evaluation of Ceramic Membrane based Iron & Arsenic Removal Plants, Standardization and performance monitoring (O&M) of high-capacity Ceramic Membrane module for pretreatment of Reverse Osmosis (RO) process feed water, Water analysis, Operation and maintenance of Ion Chomatograph, TOC analysis. |

|

Somjyoti Basak |

Senior Technical Officer (2) |

Membrane synthesis and membrane material preparation, zeolite membranes, pervaporation, Gas Chromatography, Bubble point porosimetry, operation of 1600 degree Celsius hanging firing furnace, operation and maintenance of twin screen extruder. |

|

Sanjukta Roy |

Senior Technical Officer (1) |

Ceramic polymer composite membranes synthesis, membrane material preparation, operation of ultrafiltration set up. |

|

Ashis Kumar Mohanty |

Technical Assistant |

Operation and Maintenance of water and oil filtration units, Ion Chromatography, Gas Chromatography |

|

Avurla Madhu |

Technical Assistant |

Operation and Maintenance of water and oil filtration units, Gas Chromatography |

|

Smarajit Ghosh |

Technician (2) |

Operation and maintenance of water distillation units, analytical balances, muffle furnace, air oven, operation and maintenance of twin screen extruder, operation and maintenance of Gas Chromatogrpah, Kjeldal Nitrogen analysis, microbiological analysis of water. |

|

Gouranga Chalak |

Technician (2) |

Fitting of module & permeability determination, Dimension measurement of ceramic tubes. Operating the Extruder & Mixture machine. |

|

Nitai Chand Singh |

Technician (1) |

Operation & Maintenance Ultra filtration & nano filtration testing unit for treatment of aqueous & non-aqueous solution (Rice bran oil), Operation & Maintenance of Tintometer, Furnaces, Attrition mill, Porometer. Nomenclature of ceramic tubes & Fitting of modules. Industrial & Field operation of ceramic membrane pilot units in Sugar Industry & Veg. oil Industry. |

|

Santanu Koley |

Technician (1) |

Operation and Maintenance of water and oil filtration units, furnaces, Porometer. |

Scholars/Students

|

Name |

Status | Project | Supervisor |

| Hillol Acharjee | AcSIR PhD scholar & Project Associate-II | MLP 0310 | Dr. Nandini Das

Senior Principal Scientist |

Nilanjan Santra |

DST-INSPIRE

Junior Research Fellow & AcSIR PhD scholar |

GAP 1537 | Dr. Nijhuma Kayal, Senior Principal Scientist |

Krishanu Bhowmik |

Project Associate-I & AcSIR PhD scholar | CSIR FBR | Dr. Ganesh Chandra Sahoo

Principal Scientist |

Anirban Ray |

UGC NET Fellow | Dr. Sourja Ghosh, Senior Principal Scientist |

|

Faisal Ali |

Junior Research Fellow (Project) | HCP-0054 (WP-20) | Dr. Mahesh Kumar Gagrai

Senior Scientist |

| Shanti Singh | Project Assistant | HCP-0047 | Mr. Swachchha Majumdar Chief Scientist

|

| Avijit Das | AcSIR PhD Scholar & Project Associate -II | HCP-0048 | Dr. Nandini Das

Senior Principal Scientist |

| Dr. Laboni Das | Research Associate – II | GAP 0389 | Mr. Swachchha Majumdar

Chief Scientist |

| Subhrajyoti Ghosh | Senior Project Associate | HCP-0054 (WP-28) | Dr. Sourja Ghosh |

Dr. Monalisha Samanta |

Research Associate – I | GAP 0391 | Dr. Sourja Ghosh |

|

Koushik Ghosh |

Project Associate – II | HCP-0054(WP-28) | Dr. Sourja Ghosh |

|

|

Project Associate – I | HCP 54 (WP-20) | Dr. Mahesh Kumar Gagrai |

|

Ajay Kumar Rajak |

DST-INSPIRE Junior Research Fellow & AcSIR PhD scholar | GAP 1536 | Dr. Sourja Ghosh |

Last Updated on June 26, 2025