English | हिन्दी

সিএসআইআর-কেন্দ্রীয় কাঁচ ও সেরামিক গবেষণা সংস্থা

सीएसआईआर-केंद्रीय काँच एवं सिरामिक अनुसंधान संस्थान

CSIR-Central Glass & Ceramic Research Institute

"Innovation in Ceramics and Glass for the mankind"

SGD: Areas of Research

Areas of Research

1. Strategic Sector:

Space grade optical glass

|

Optical glasses developed by CSIR-CGCRI with stringent properties |

- Radiation Shielding Window Glass

High Density (d = 5.2 gm/cc) Radiation Shielding Window (RSW) Glass blocks of 1000×800×17 mm3 produced through Bottom-Pouring-Flow-Casting Technique using 40L Platinum Pot Pilot Facility

|

3.61 g/cc Density Stabilized RSW Glasses |

4.77 g/cc Density Stabilized RSW Glasses |

|

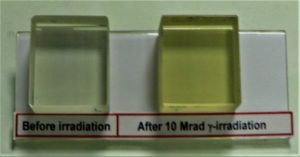

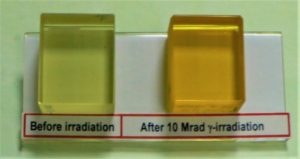

Glass samples sustain a cumulative γ-radiation dose of 10 Mrad |

|

|

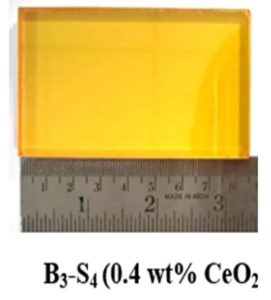

Development of cost effective bismuth based radiation shielding glass for nuclear hot cell application |

|

|

Developed stabilized Bismuth Glass using melt-quenching technique |

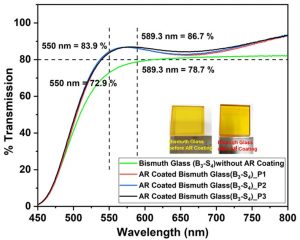

%Transmission enhancement on AR coated bismuth glass of 10 mm thickness (Here P1, P2, P3 indicates different positions of the same glass during measurement of transmission spectra) |

|

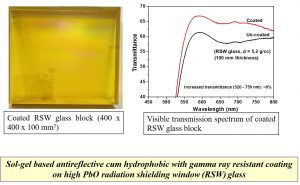

Coated RSW glass block (400 x 400 x 100 mm3) |

Visible transmission spectrum of coated RSW glass block |

|

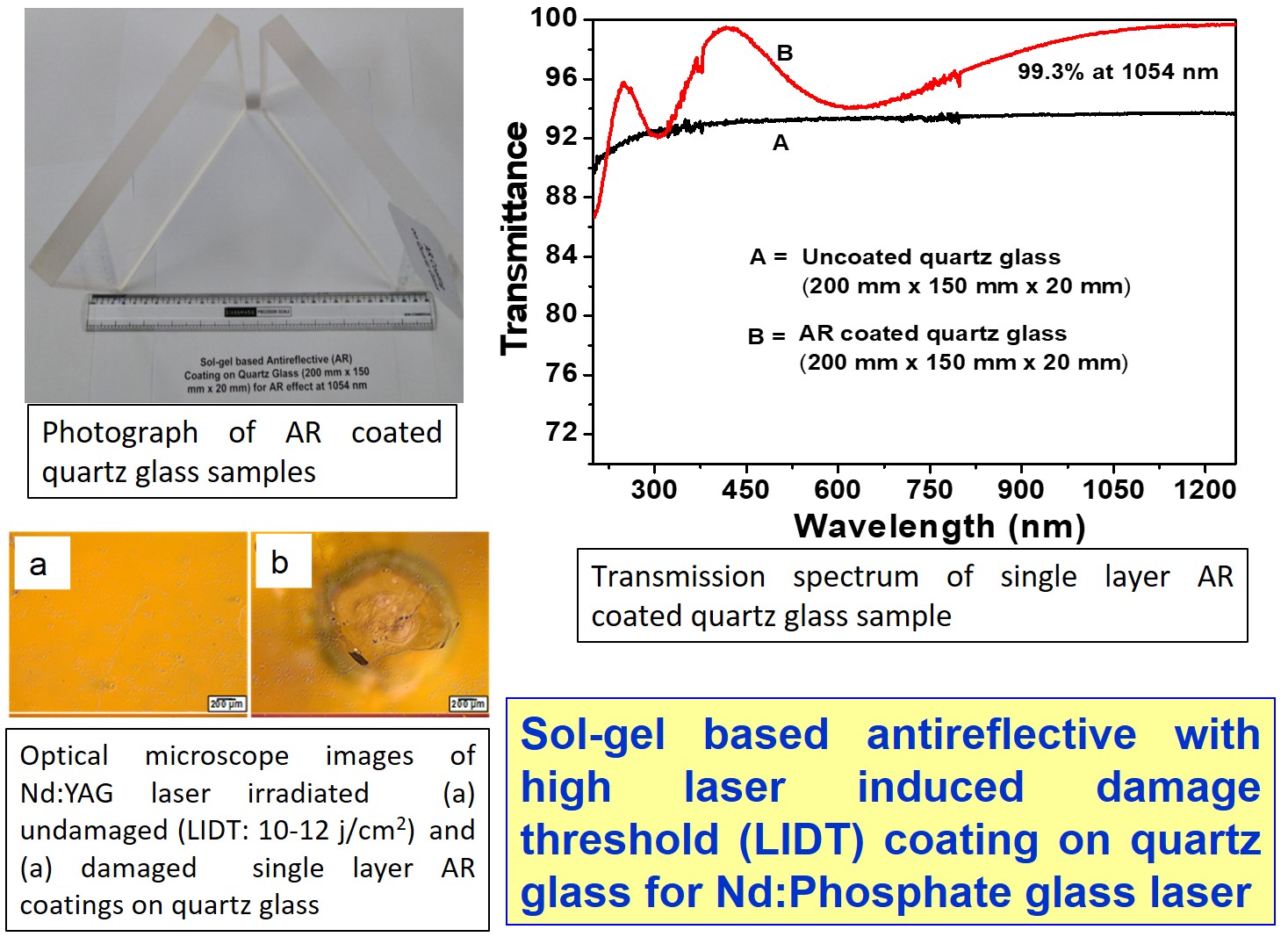

Sol-gel based antireflective cum hydrophobic with gamma ray resistant coating on high PbO radiation shielding window (RSW) glass |

|

-

Glass beads for nuclear waste vitrification

Glass Bead Material for formation of Vitrified Waste Product for Immobilization of Nuclear Wastes

- Laser and cladding glass

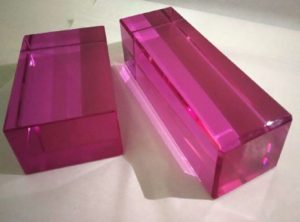

Nd doped phosphate Laser glass

Bottom pouring flow casting technique

Casting using 15 L facility

Processed Nd doped glass block

Cu doped Edge Cladding Glass

-

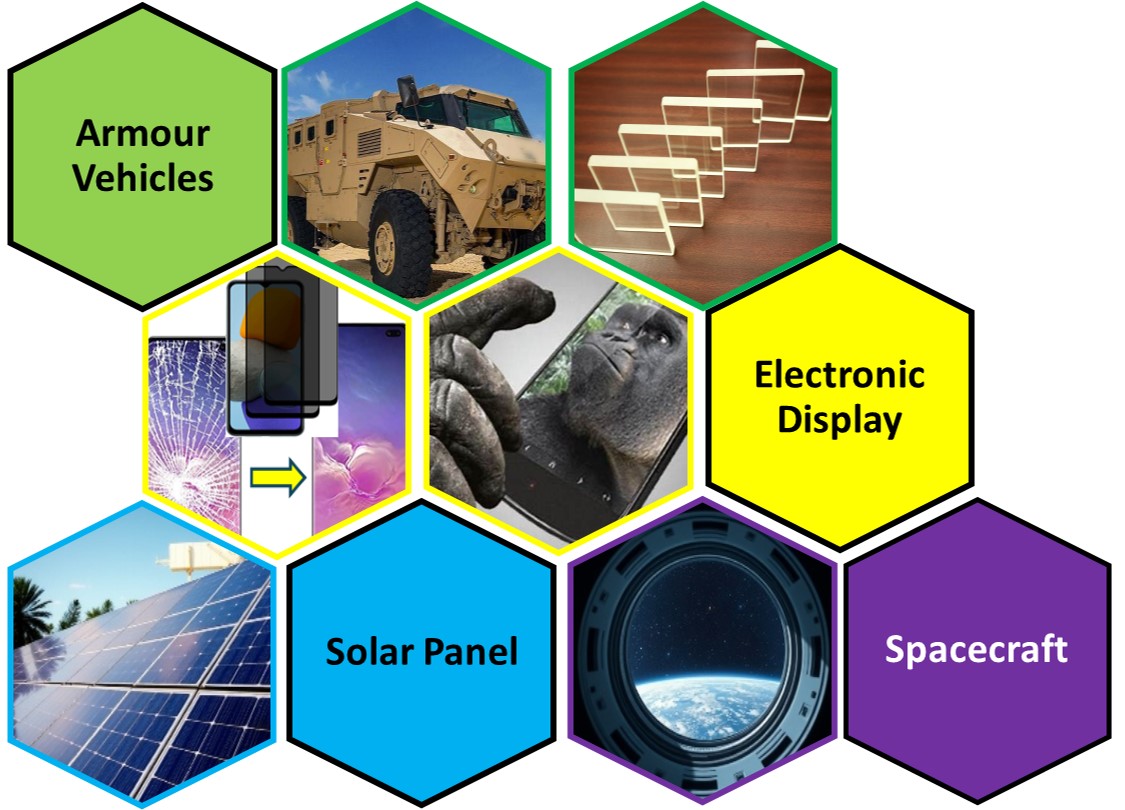

High Strength and transparent glass-ceramic

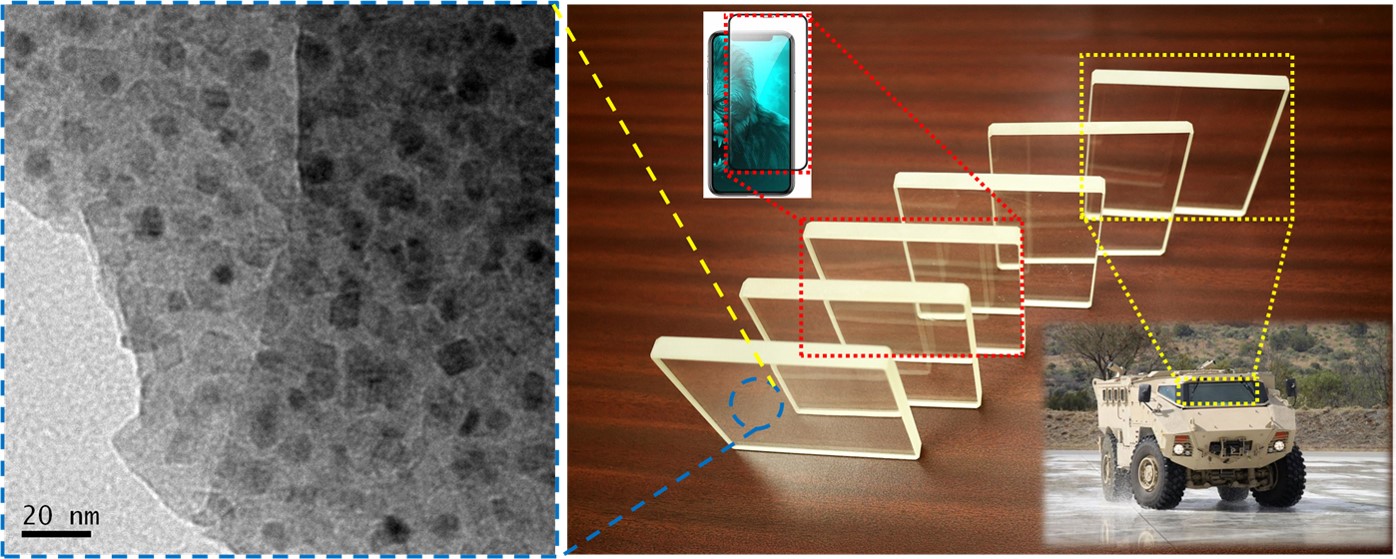

HIGH STRENGTH AND TRANSPARENT NANOCRYSTALLINE GLASS-CERAMIC

High strength and transparent nanocrystalline glass-ceramic for armor vehicle and electronic display applications

- Chalcogenide glasses for infrared optics and IR photonic devices

|

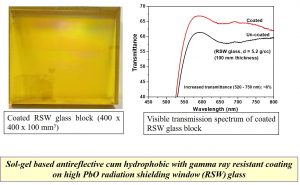

Transmission Spectrum |

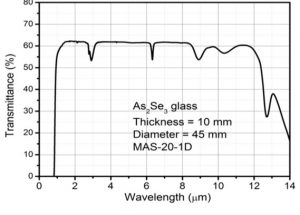

Chalcogenide glasses |

Image formation |

2. Societal Sector:

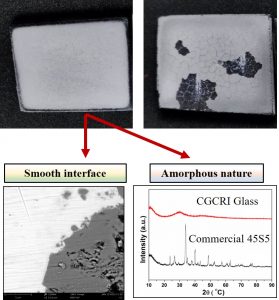

- Formulation of novel bioactive glasses for bone graft and coating applications

|

|

|

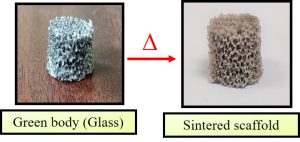

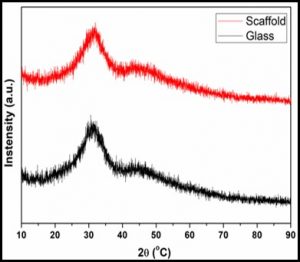

Amorphous scaffold prepared through optimized heat treatment using novel borosilicate based bioactive glass |

|

|

|

CGCRI developed High CaO containing Bioactive glass matching thermal expansion coefficient with that of metallic implants suitable for adherent, crack-free coating |

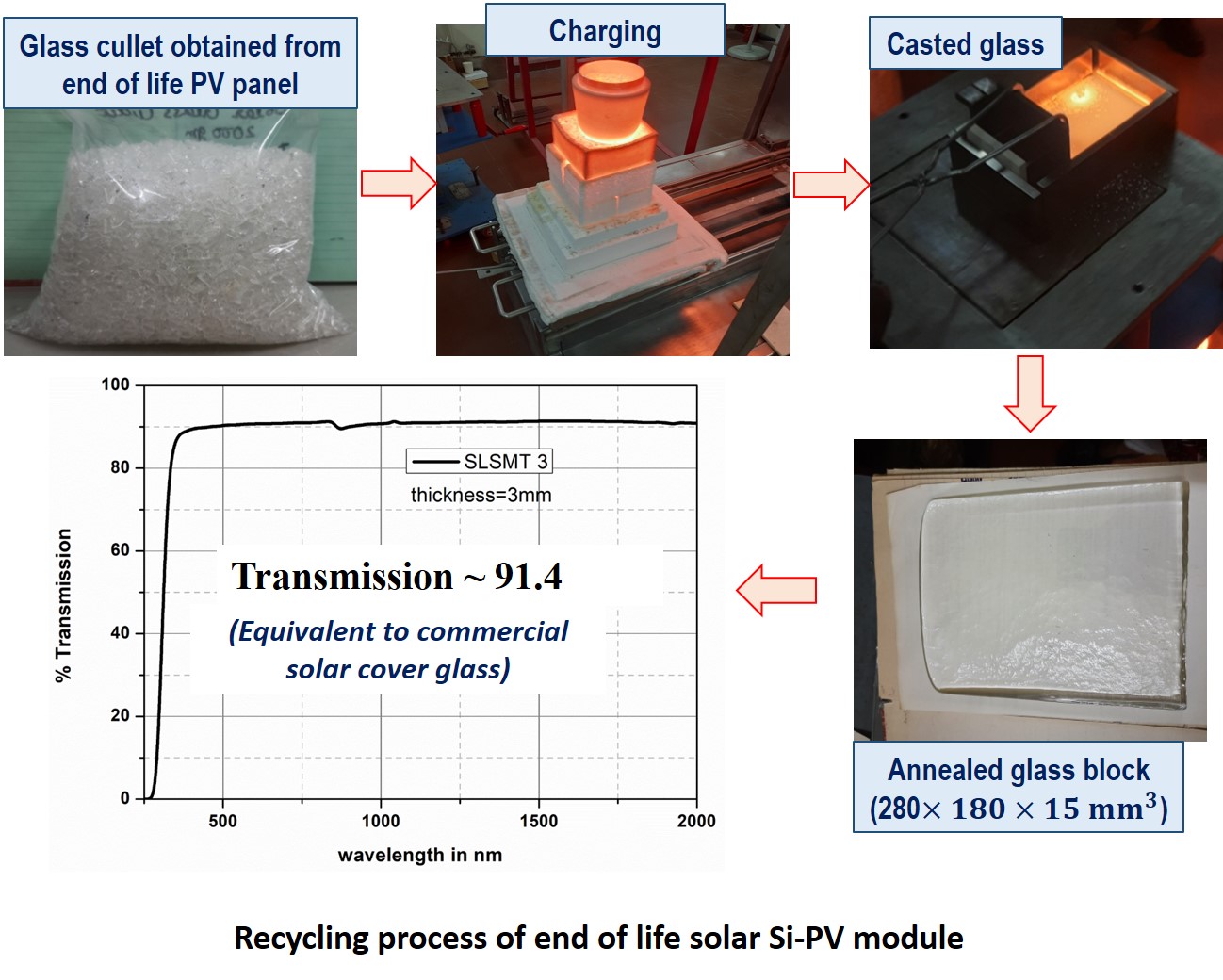

3. Energy and environment:

- Development of Glass Foam bricks

Light weight Glass Foam bricks for insulation and construction application

Compressive strength 3-5MPa; Thermal conductivity: 0.1-0.2 W/m K

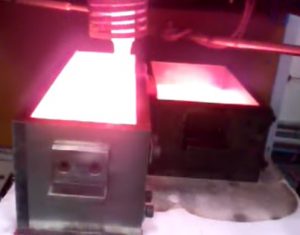

- Energy efficient microwave melting of glass

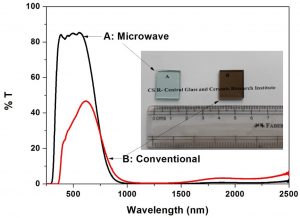

Heat Absorbing glass prepared in microwave heating in air atmosphere retaining predominantly Fe[II] in glass, unlike Fe[III] in conventional heating

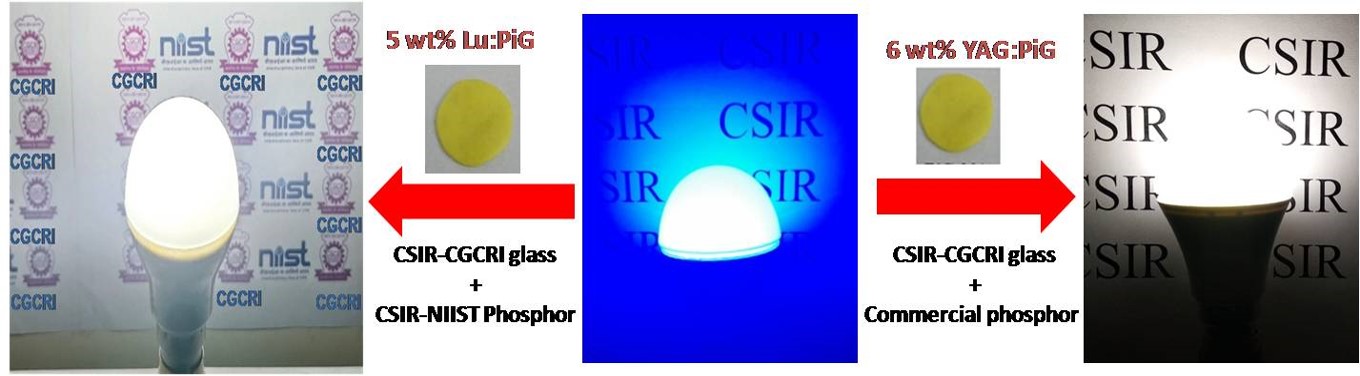

- Phosphor-in-Glass (PiG) composites for high power white LED

Optical filter for solar radiation splitter

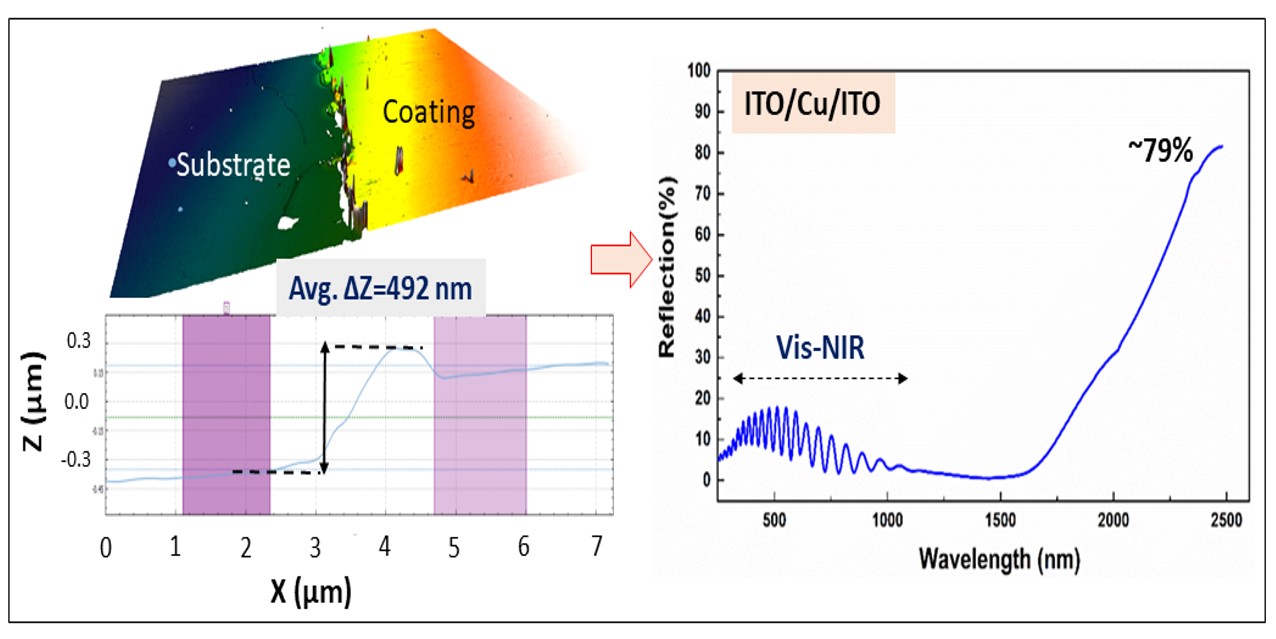

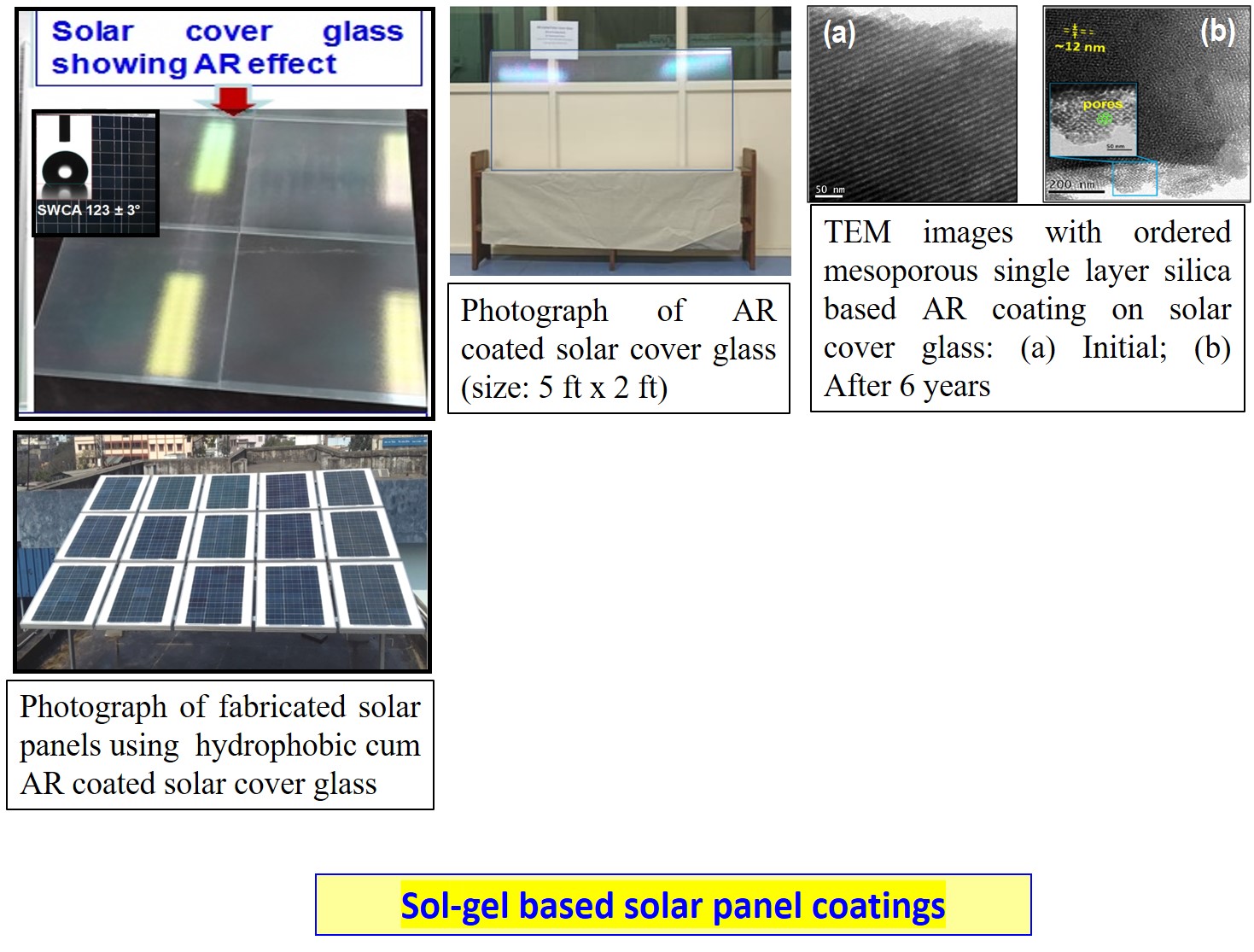

- Sol-Gel Coatings

4. Computational Material Research:

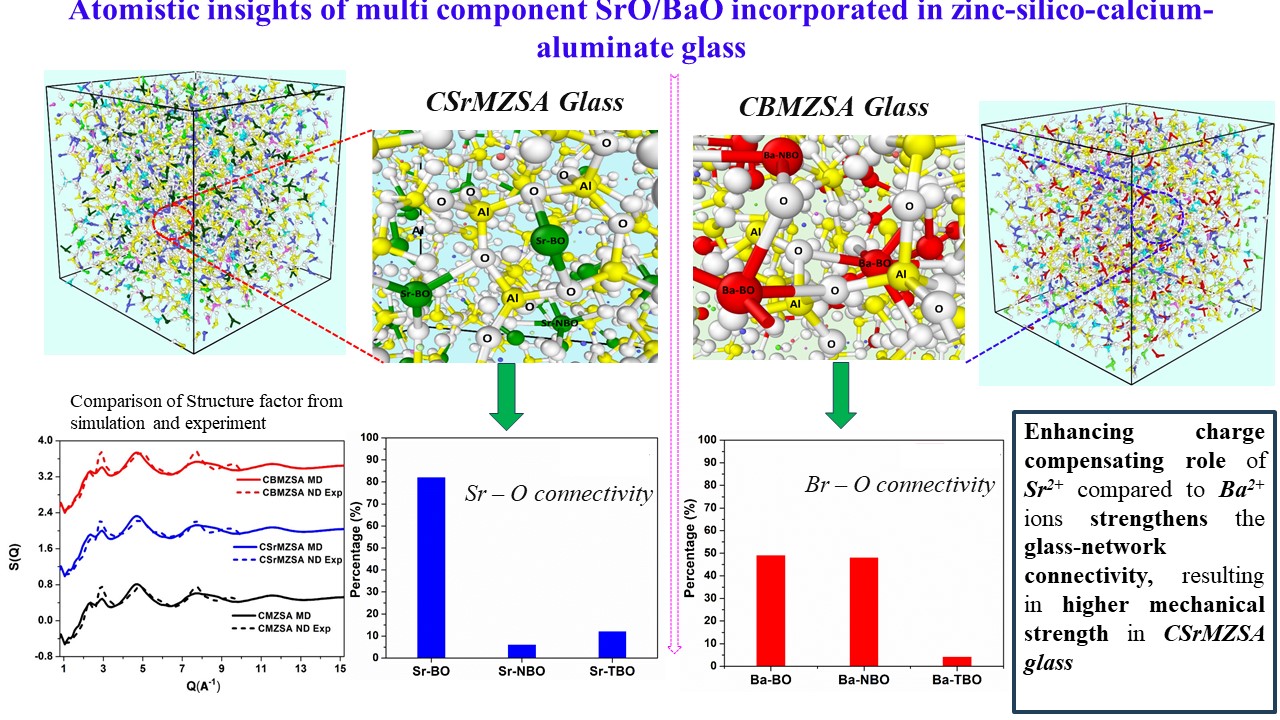

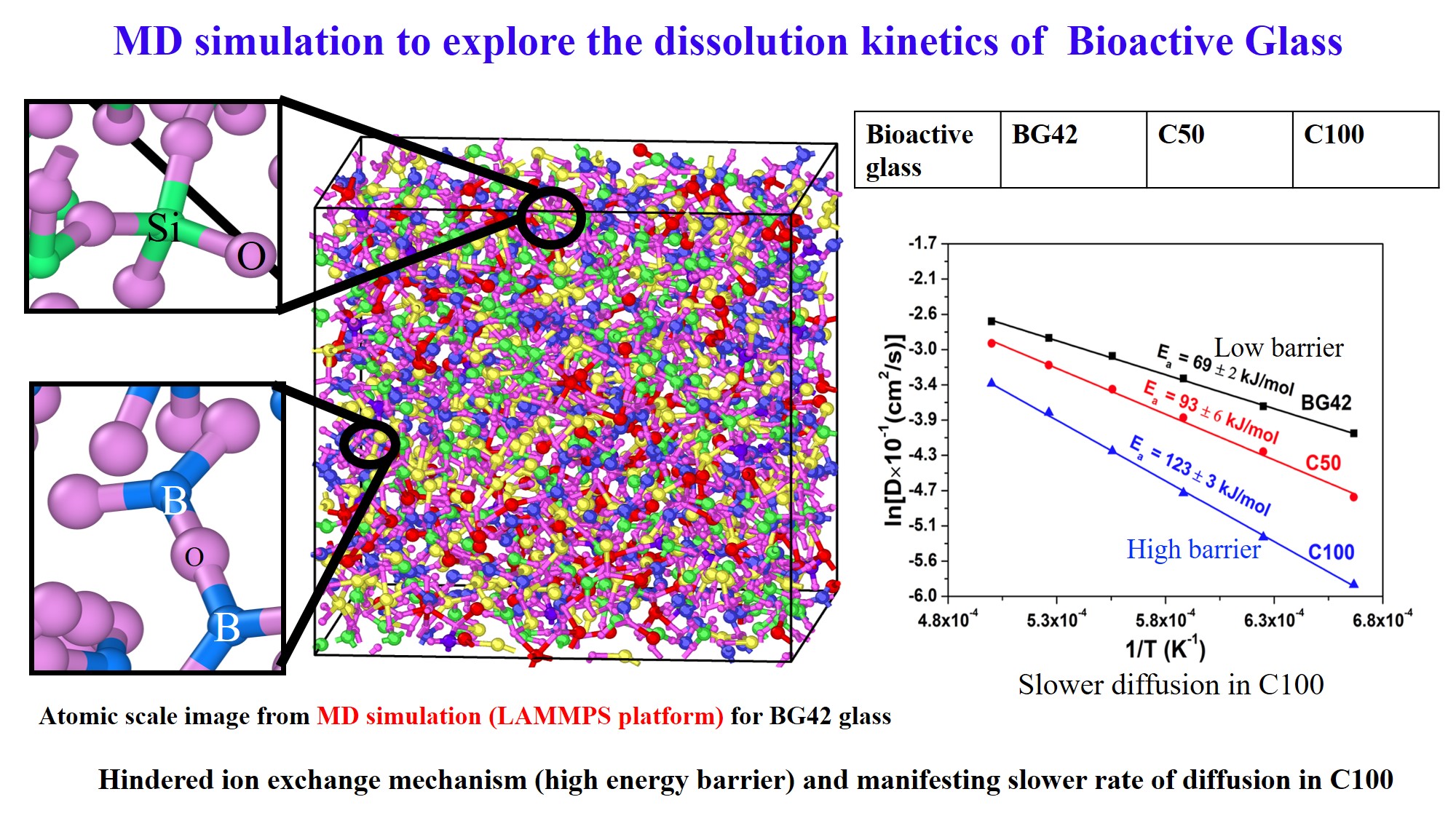

- Atomistic glass insight: Advancing research through simulations

Last Updated on July 9, 2025